Create, Customise, Deliver

Create, Customise, Deliver

When off-the-shelf options fall short, our team at Design Quintessence develops tailored solutions to meet the specific demands of our industry. These purpose-built components often lead to entirely new products—creations that didn’t exist before but are now part of our exclusive range. For 30 years, DQ has delivered smart, effective design solutions to the event, production, theatrical and touring industries. Whether it's a custom truss centrepiece, unique rigging configuration, specialised road or flight case, or a custom colour finish, DQ has the capability and experience to meet your requirements.

If we don't have a solution, then a solution doesn't exist... yet!

Showcasing Creations: Custom Designs, Products & Ideas

Select a tab to explore projects, products and ideas.

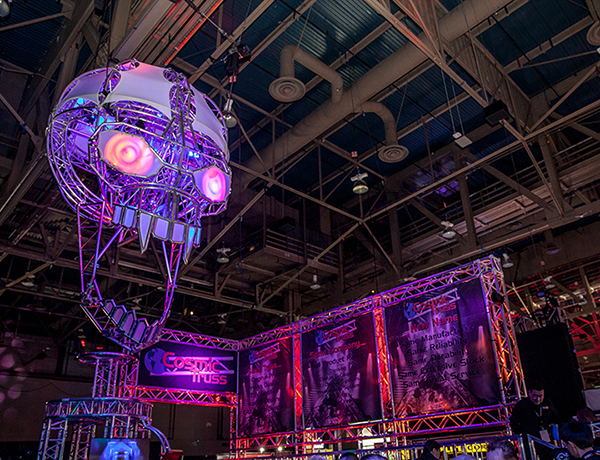

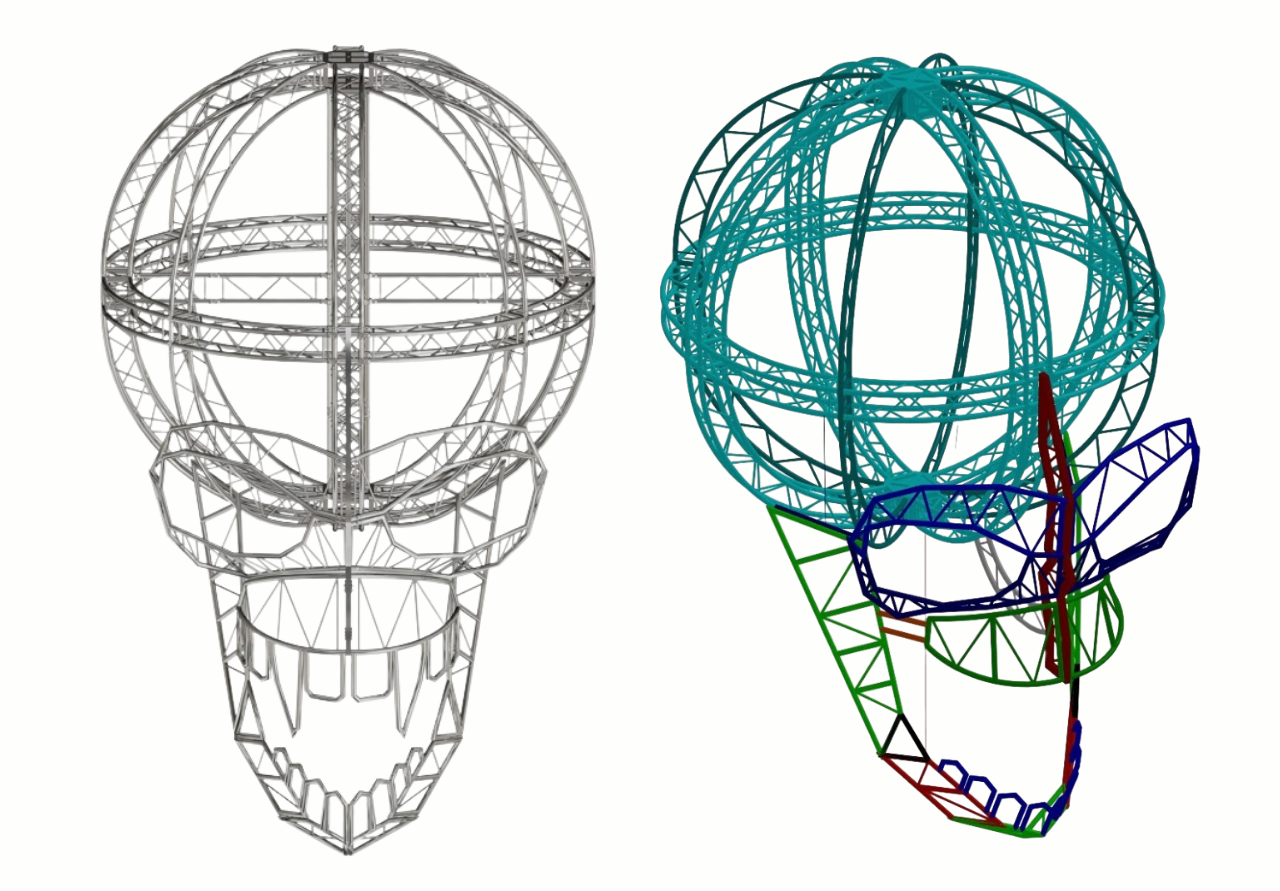

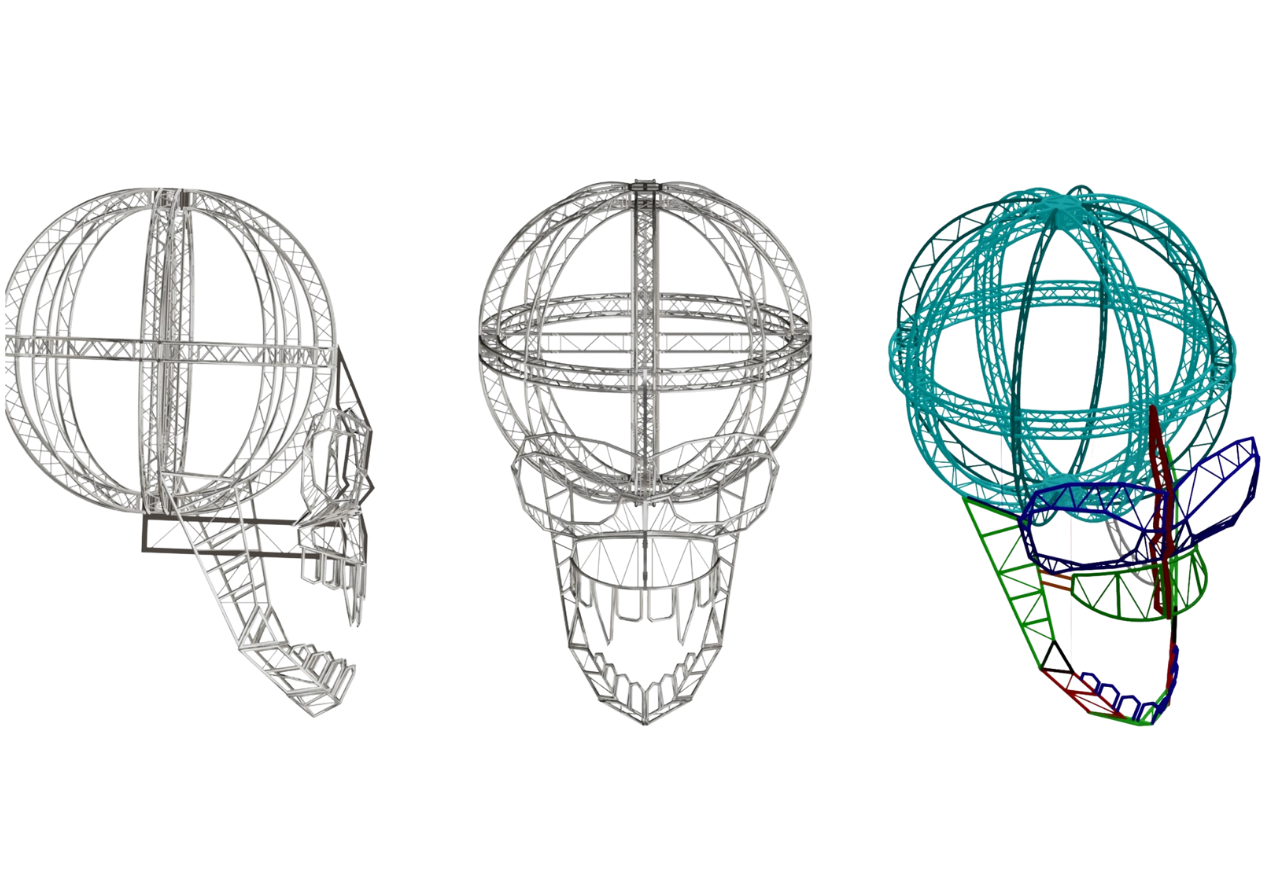

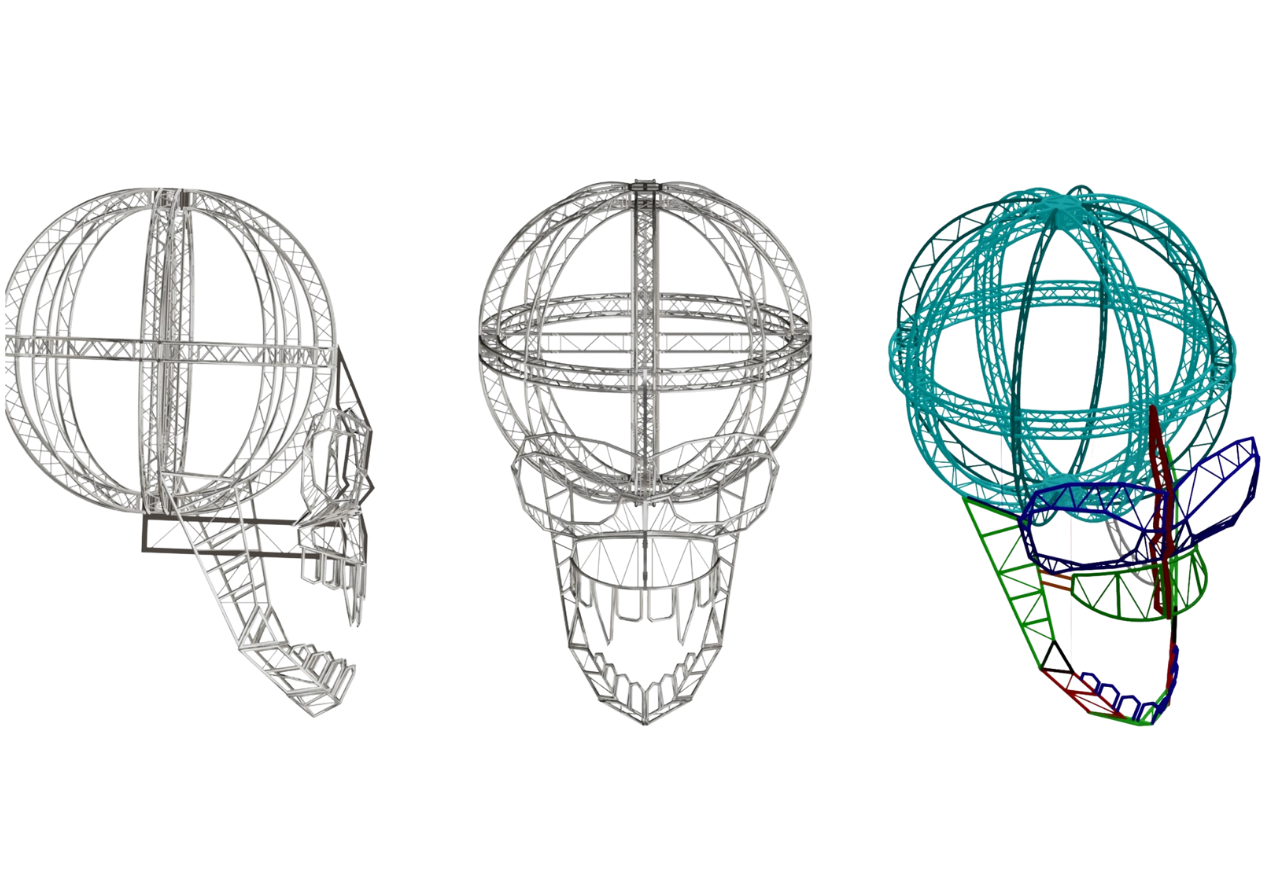

Truss Skull

Brief: Can we build a skull from truss?

Solution: Here at DQ we believe truss can be used to build anything so of course the answer was “Yes!” This 9m tall truss skull was one of our most challenging custom truss designs as it took a while to get the form and “personality” of the skull right.Trepidation from factory staff in making and building such an unusual structure soon turned into excitement and pride when they completed the fabrication.

As with any custom designs, we used as many standard truss components as we could so that they could be used in other everyday applications (ensuring the production company achieves a much faster return on investment).

The skull structure has won an international award and been copied in countries as far afield as Mexico City.

Custom Guitar Truss

Brief: Build a large scale replica of Brian May’s guitar for a WA pro-am production of “We Will Rock You”

Solution: Scanning and tracing a CAD drawing of his actual guitar allowed us to create a design using custom and standard truss components that followed the outline of the actual guitar pretty closely.

With a guitarist sitting and playing inside the 8m long truss guitar whilst it is slowly lowers from the ceiling down onto stage ensures that the grand finale makes a lasting impression on all those who see the show.

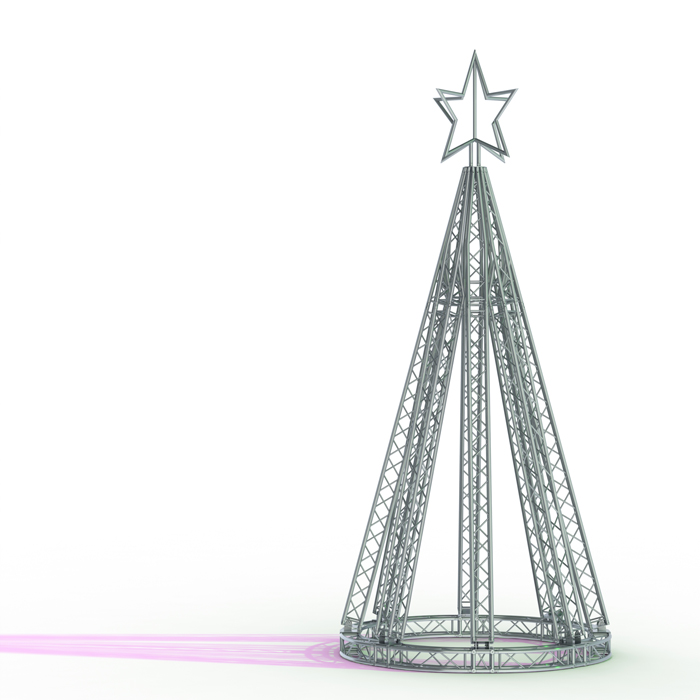

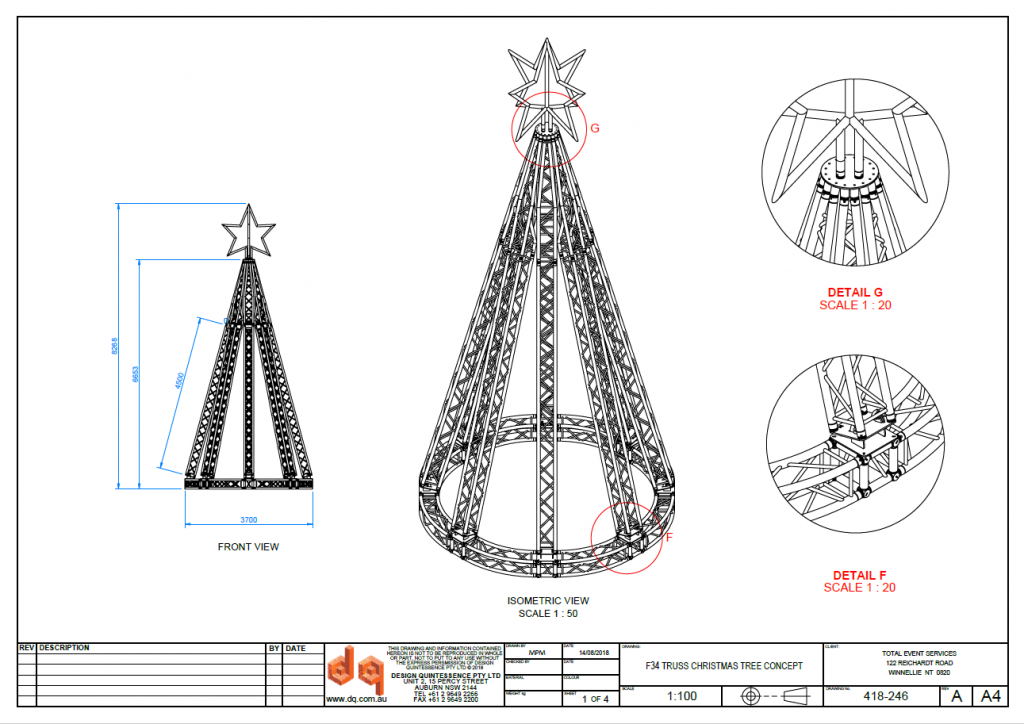

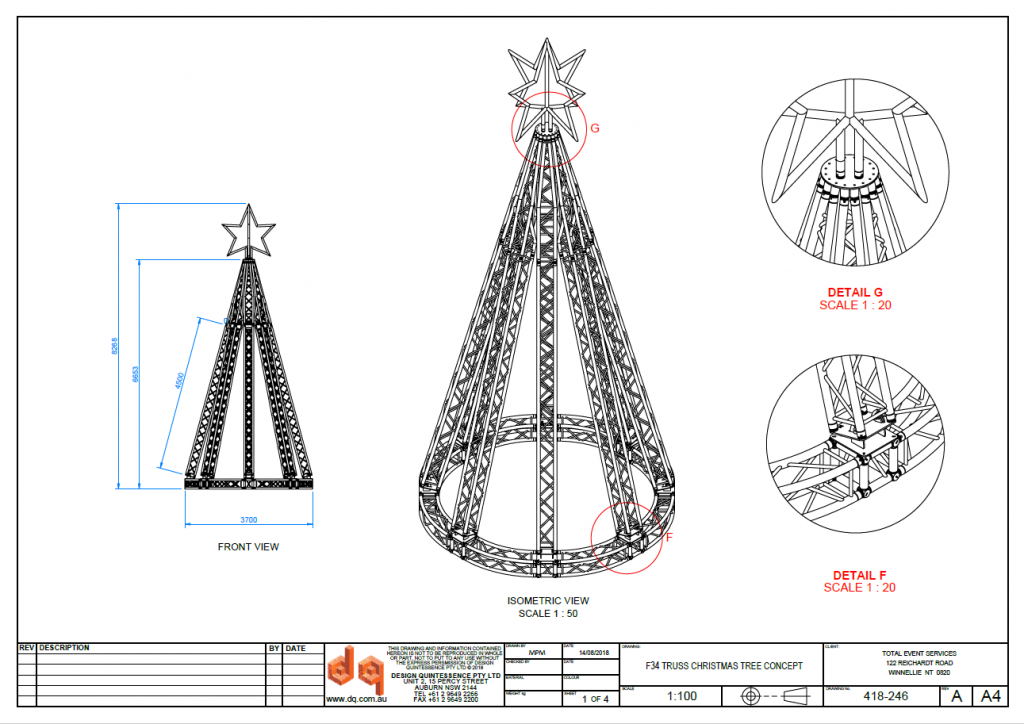

Truss Christmas Tree

Brief: Design a large Christmas tree out of truss, to be erected in Darwin’s George Brown Botanical Gardens.

Solution: The 8.0m truss structure had to be built from standard components and easy to rig for its short-term installation. It also needed to withstand storms with winds up to 187 km/h in Darwin’s extreme weather.

The conical shape of the tree body was achieved using our new product, the GT F34 variable junction, which facilitates incremental connection of truss pieces from 0 to 25 degrees. To bring all the beams together, we designed a special linear truss with box configuration on the bottom and flat configuration on the top. This resulted in three unique angles converging at the top of the truss tree. To resolve this, we designed and fabricated a custom spigot adaptor that neutralised all spatial angles, allowing them to align with a single flat steel plate at the peak.

“The entire structure came together beautifully, without faults!” Colin West, managing director of Total Event Services exclaimed.

The truss tree was both robust and easy to rig, made possible by our expert design team. Thanks to streamlined manufacturing, all custom parts were delivered on time for the season.

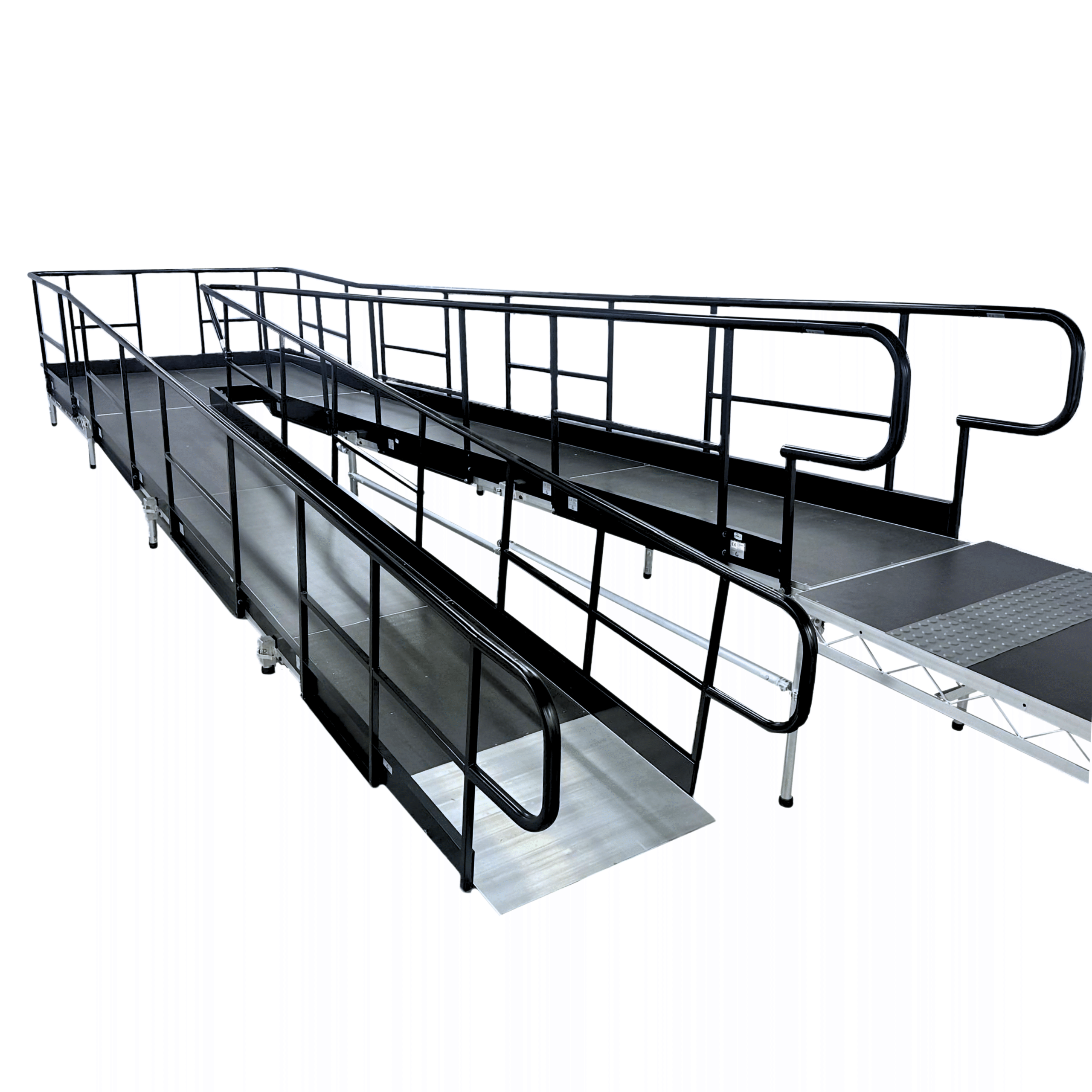

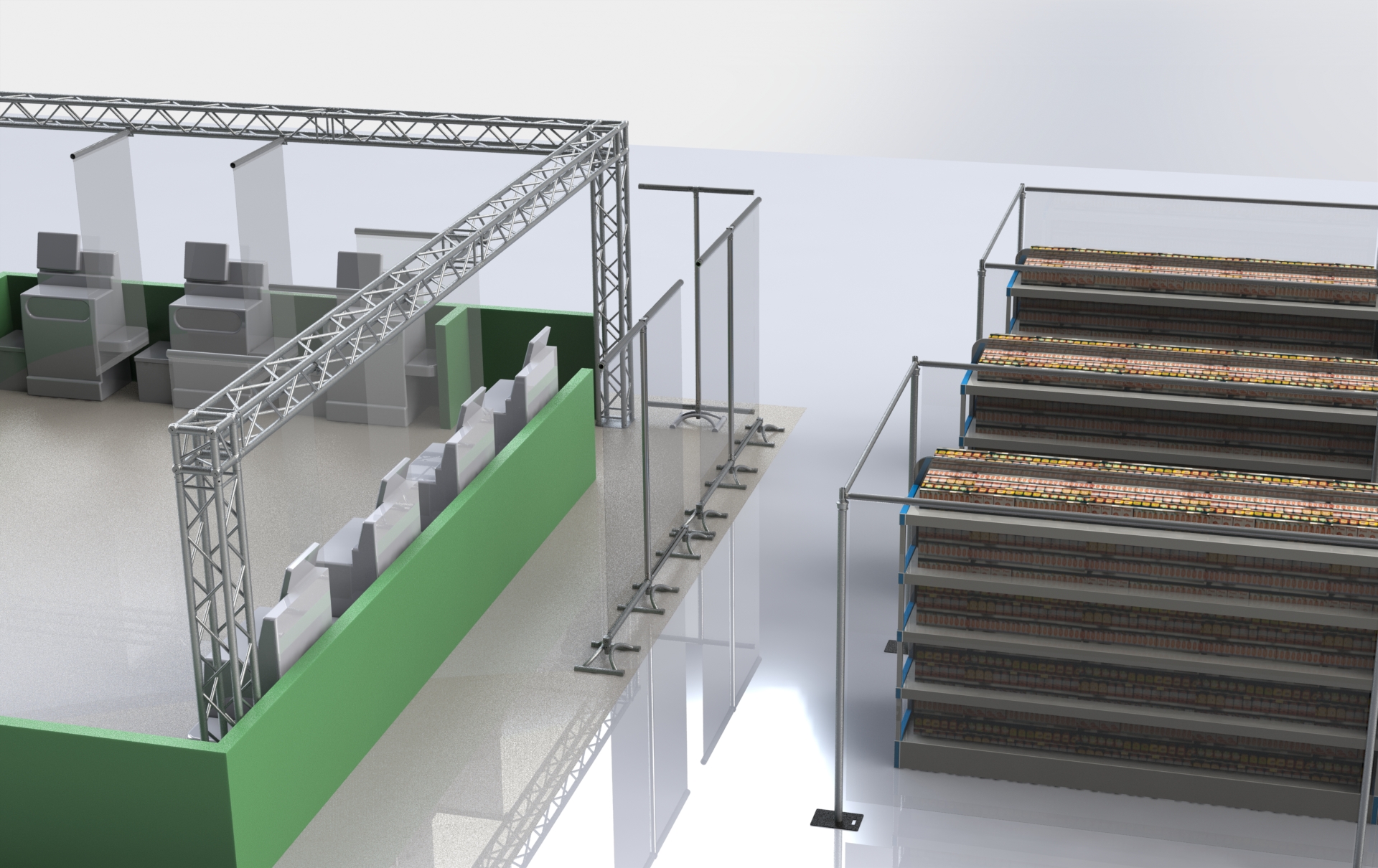

Modular Access Ramp

Brief: Design Quintessence developed the Modular Access Ramp to deliver an Australian Standard compliant accessibility solution for stages, schools and event venues.

Solution: Modular Access Ramp – Engineered Accessibility Ramp for Wheelchair and Pedestrian Access

Developed over several years in response to industry demand, the Global Truss Modular Wheelchair Access Ramp by Design Quintessence offers a professional, fully engineered solution for accessibility to stages and elevated areas. Purpose-built for wheelchair and pedestrian access, this system meets Australian Standards and is designed specifically for event venues, schools and staging environments. With durable, modular construction, the ramp accommodates landing heights from 300mm to 900mm and provides a safe 1:14 incline for smooth, compliant access. Featuring a 1000mm wide ramp, curved and continuous handrails, tactile indicators and expanded landings for improved wheelchair manoeuvrability, the ramp system ensures safety and inclusivity. Compatible with standard stage decks and offering configurable left-turn, right-turn, and wraparound layouts, this ramp is ideal for festivals, theatres, schools, and venues requiring permanent or temporary accessibility solutions without compromising structural integrity.

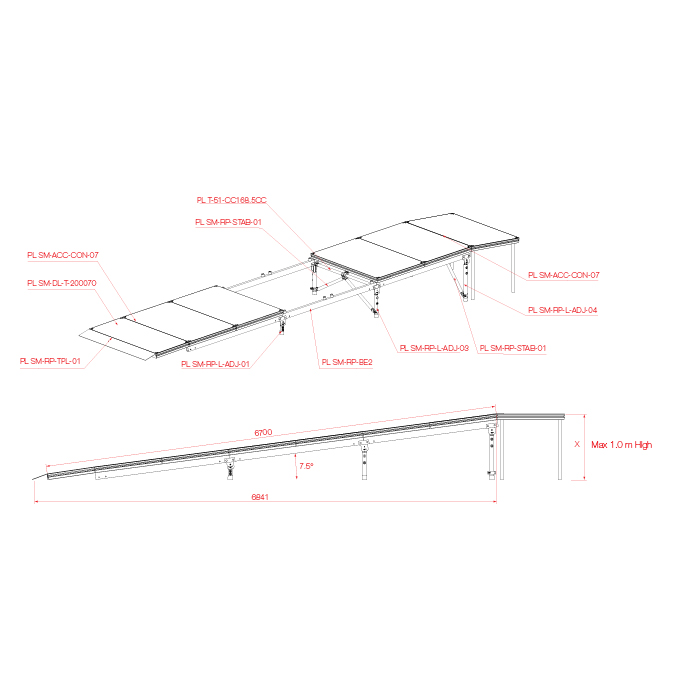

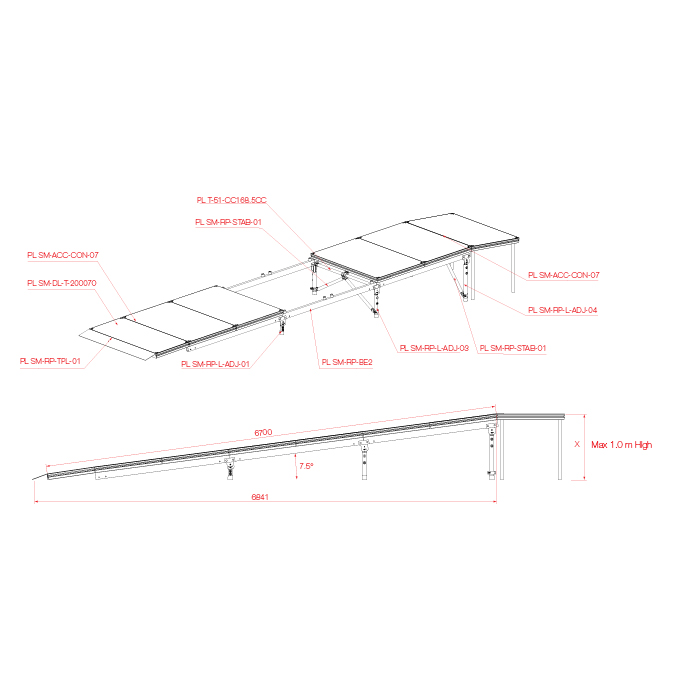

Stage Car Ramp

Brief: To meet the demand for a heavy-duty, adjustable ramp solution, Design Quintessence engineered the Stage Car Ramp specifically for safe vehicle and equipment access on stages in event and production environments.

Solution: Stage Car Ramp – Heavy-Duty Vehicle and Equipment Access Ramp for Stages

The Stage Car Ramp (SKU GT-STG-CARAMP) is a robust, engineered ramp designed to provide safe and reliable vehicle and equipment access to stages and elevated areas. Constructed with a non-slip 17mm plywood top board and an aluminium entry ramp, it delivers excellent traction and stability for heavy loads.

Adjustable legs allow precise height adaptation to fit various stage elevations, making it highly versatile for both temporary and permanent staging setups. Engineered to withstand substantial weight, the Stage Car Ramp is ideal for theatres, festivals, exhibitions, and production venues requiring robust logistics solutions.

This ramp ensures compliance with safety standards while facilitating efficient load-in and load-out operations for vehicles and crew equipment.

Camera Riser Kit

Brief: The Global Truss Camera Riser Kit was developed to meet the need for a stable, professional-grade platform solution for tripod-mounted cameras at live events, festivals, and broadcast environments.

Solution: Global Truss Camera Riser Kit – Two-Tier Modular Camera Platform System

The Global Truss Camera Riser Kit is a purpose-built, two-tier riser system designed to provide elevated, stable camera positioning for professional filming and live production environments. Engineered to improve sightlines and bypass audience obstruction, the system separates the tripod from the operator on dual non-slip platforms, reducing accidental camera movement and ensuring steady, high-quality footage.

Featuring adjustable legs for flexible height configurations, the kit adapts to different venue layouts and filming requirements. The lower platform supports the tripod on a 1.55m x 1.05m stage deck with 800mmH legs, while the upper platform provides a 1.8m x 1.2m operator deck with 900mmH legs and under-deck storage clips to secure components during transport.

For logistics and storage, the kit includes two custom-designed dollies (left and right) to securely transport the system between locations. Durable, stable, and engineered for demanding environments, the Global Truss Camera Riser Kit is ideal for sporting events, concerts, festivals, and live broadcast productions where professional camera support is critical.

Ovation Motorised Screen Lift Case for 75" Display - Eleven Design

Brief:Eleven Design required a professional, road-ready case solution for transporting and presenting a 75” screen across various client sites and events. The case needed to protect the screen during transit while offering a clean, streamlined setup that aligned with their polished presentation style. A motorised lift was essential for ease of use and efficient setup in front-facing environments.

Solution: Design Quintessence provided a custom Ovation Motorised Screen Lift Case, tailored to the specific dimensions and handling needs of a 75” screen. The design featured heavy-duty hardware, durable construction, and a smooth motorised lift mechanism to raise the screen at the push of a button. Internal foam was precision-cut for secure placement, and the case included integrated cable access to allow for quick connectivity.

The result was a mobile presentation unit that combined protection, practicality, and professionalism in one refined package.

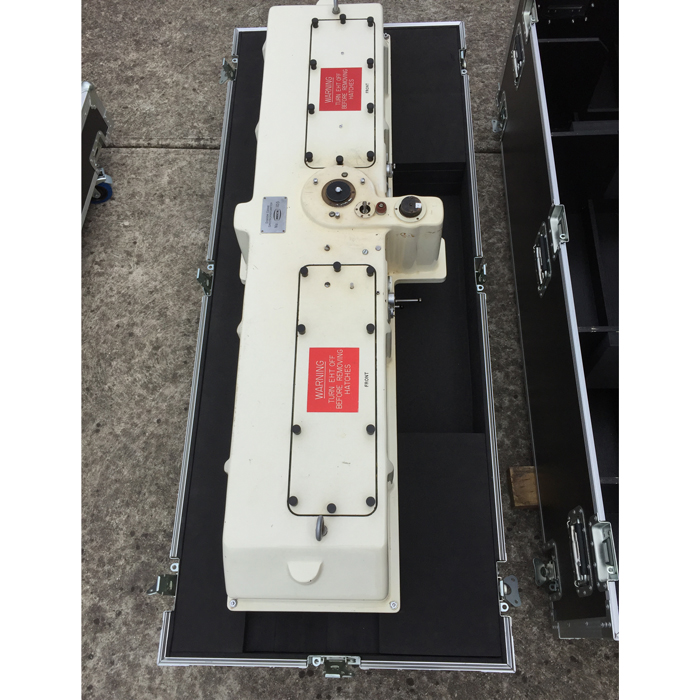

Dobson's Ozone Spectrophotometer Multi-Piece Road Case

SKU: DESIGNit-BOM-CASE

Brief: Design and build a case for a 50+ year old priceless atmospheric ozone measuring instrument and a range of accessories to safely ship it around the world.

Solution:The fact that only a handful of these instruments designed in 1924 are left operating across the world was not lost on us as we were creating a case design to protect what is an irreplaceable item.

This four piece case comprised a permanent pallet style base allowing forklift loading onto aeroplanes, a low base with detailed CNC foam fit out for the spectrophotometer, a lift-off body, separate lift-out accessory tray and a removable lid that doubles as a trolley when placed underneath for onsite manoeuvrability.

When we finished building the case it was loaded onto a plane the same week for the spectrophotometer’s next assignment in Antarctica.

TLX Custom Furniture & Tour Living Case

Brief: TLX needed a durable, all-in-one case solution to house a coffee machine and mini fridge for use during long production days while working on a show. The goal was to create a mobile hospitality setup that provided comfort and convenience backstage, without compromising on quality or portability.

Solution: Design Quintessence delivered a fully custom Ovation Case built to meet the demands of a busy production environment.

The case securely housed both appliances with reinforced compartments, integrated ventilation, and reliable access to power. Precision-cut foam ensured safe transport, and smart cable management kept the setup clean and efficient.

Compact, robust, and road-ready, the case has become an essential part of TLX’s production kit—keeping the crew fuelled and ready to perform.

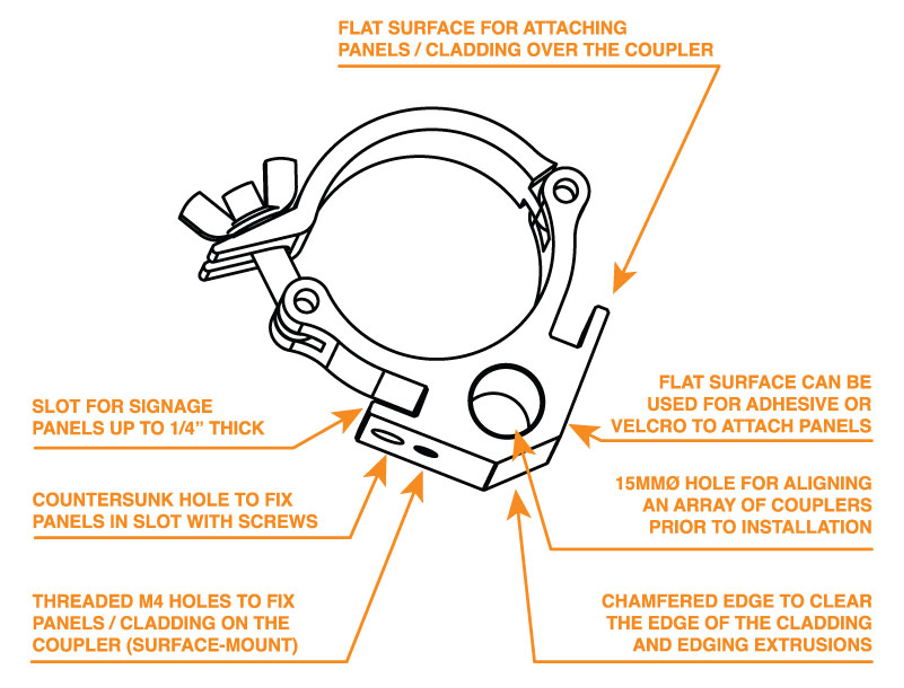

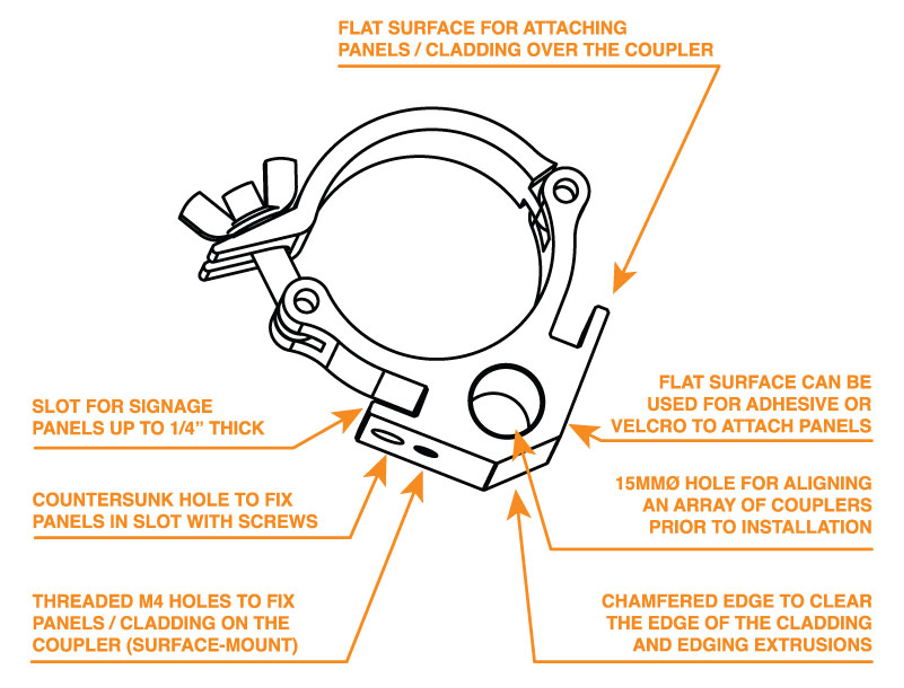

Cladding Coupler

Brief:Developed in response to a project enquiry from the Australian Museum, the Cladding Coupler from Design Quintessence offers a versatile solution for mounting panels directly onto truss structures. Designed for public spaces and commercial environments, it enables fast, secure installation of various cladding materials—ideal for exhibitions, architectural applications, signage, and temporary barriers. The modular coupler uses integrated slots, M4 screw fixing points, or Velcro and adhesives to suit multiple mounting styles. Made to work with Global Truss systems, this purpose-built solution is now in stock and widely adopted.

Solution: The Design Quintessence Cladding Coupler is a multi-functional truss accessory designed to simplify cladding and panel mounting for Global Truss structures. Developed through extensive research and real-world testing, the coupler supports transparent acrylic panels, MDF boards, signage, and architectural panels using integrated slots, precision M4 screw points, or adhesive methods. Popular for truss climb prevention, exhibition cladding, set installations, and commercial signage, this innovative attachment was launched at Entech Show 2022 and has received strong market feedback. Engineered for strength and ease of use, the Cladding Coupler is now available from Design Quintessence.

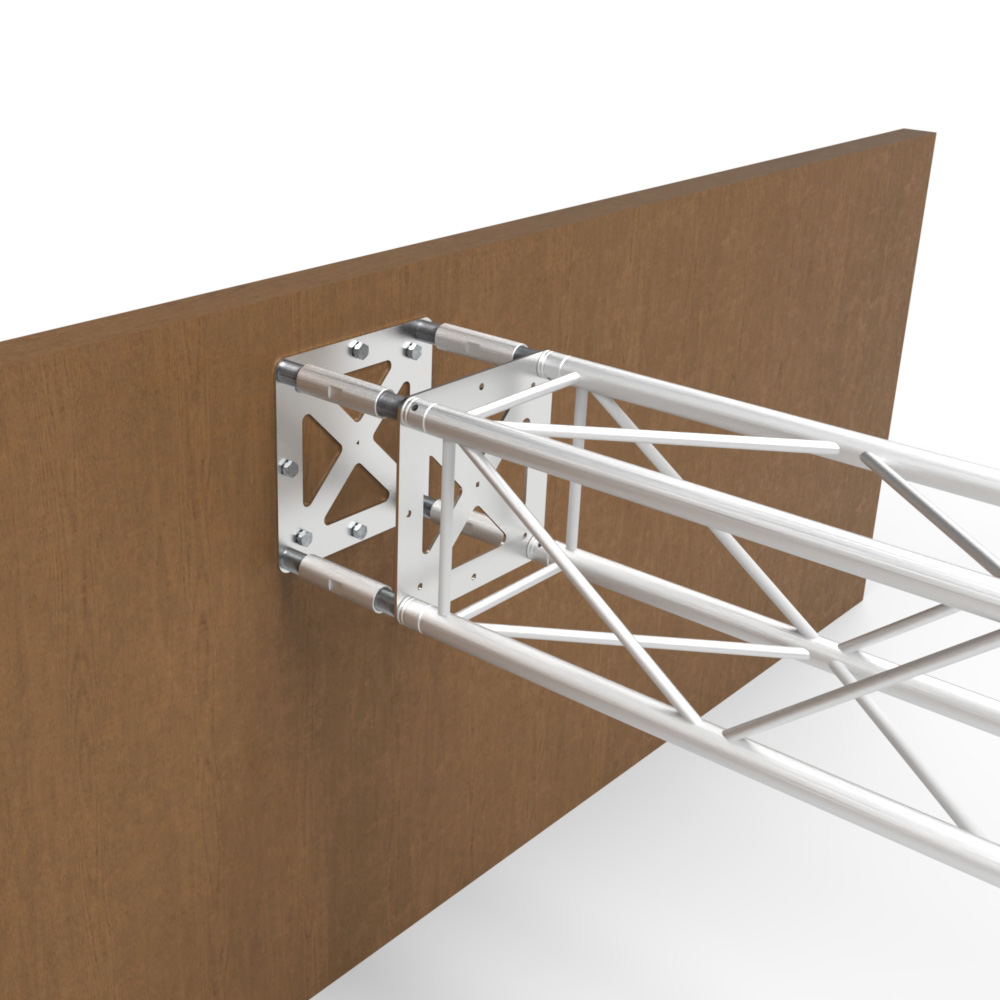

Truss Extender

Brief: The Adjustable Truss Extender from Design Quintessence is engineered to simplify wall-mounting and structural spacing for aluminium truss systems. Specifically designed for F34 and F44P truss, this extender creates a secure connection point to walls or uneven surfaces, allowing truss structures to be installed safely in restricted or awkward spaces.

Manufactured from heavy-duty 6mm steel and featuring multiple bolt holes, it provides strong, stable support for truss installations in entertainment venues, stages, and commercial environments.

Solution: The Adjustable Truss Extender is a reliable mounting solution for attaching F34 and F44P aluminium truss systems to walls or other surfaces. By creating a precise gap between the truss and mounting surface, it allows essential clearance for cables and equipment while ensuring a clean, professional installation.

Made from 6mm steel plates and designed with multiple fixing points, this extender serves both as a wall-mount bracket and a structural leg extender for uneven ground. It’s ideal for tight spaces where direct truss mounting isn’t possible, supporting safe and efficient installations of lighting and AV equipment.

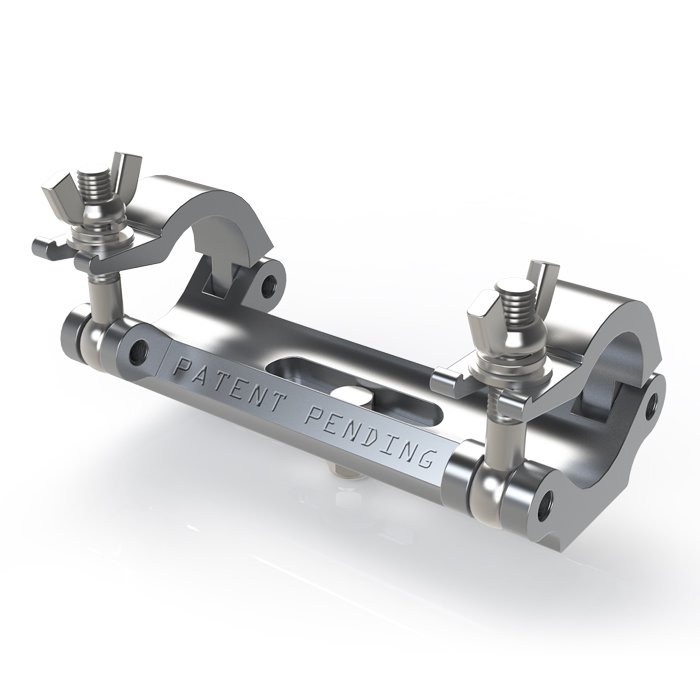

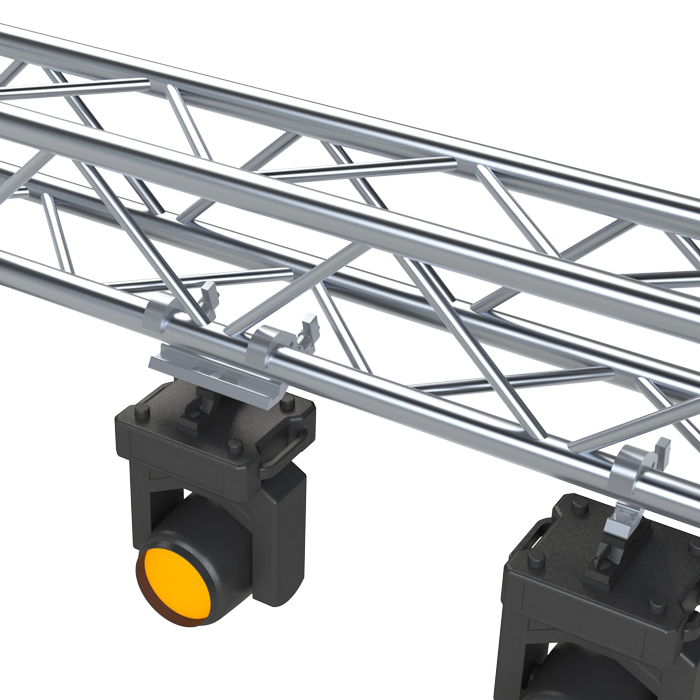

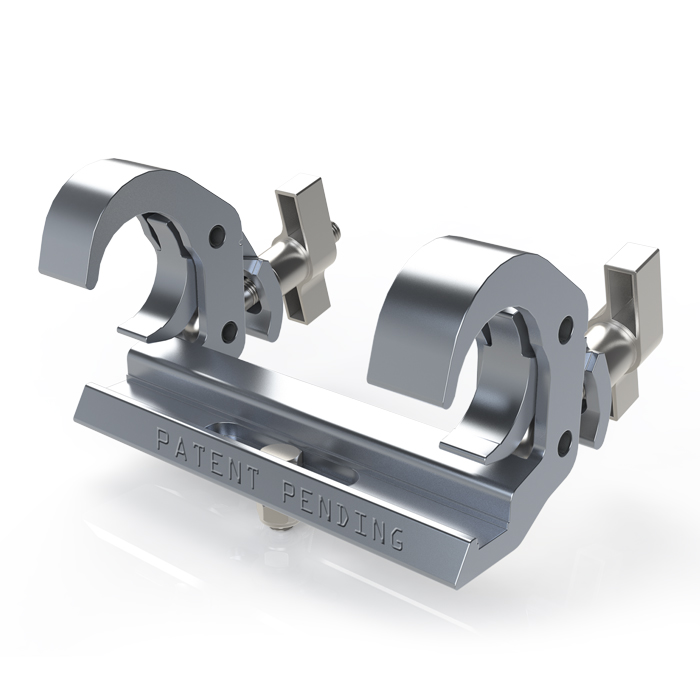

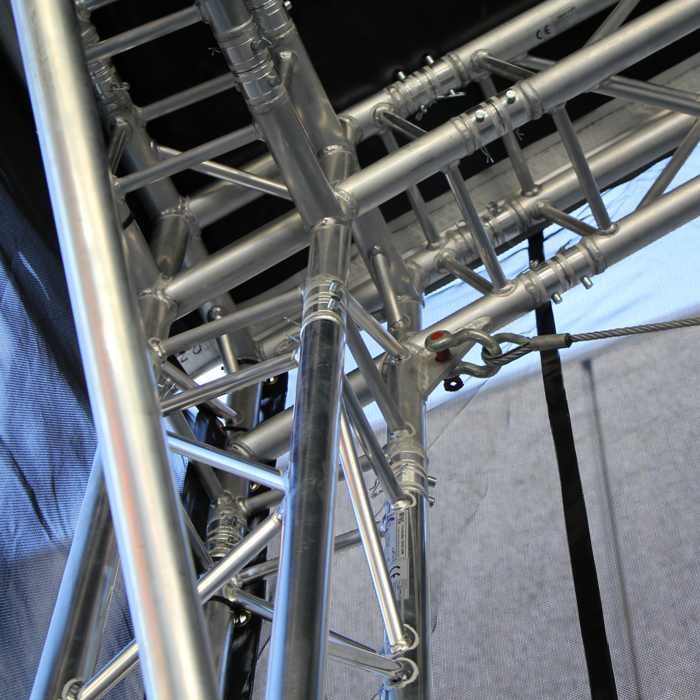

Twin Conjoined Coupler

Brief: The Conjoined Twin 50mmØ Coupler range from Design Quintessence solves one of the most common rigging challenges: precise fixture positioning obstructed by truss bracing. Designed for 50mm aluminium truss systems, this innovative coupler is available in two variations to suit different rigging needs: the Slimline Coupler (SWL 450kg) and the Easy Trigger Clamp (SWL 150kg). Manufactured from custom-machined aluminium extrusion, both options ensure accurate, secure fixture placement while maintaining compatibility with Global Truss systems, including F34, F44P, and 5 Chord Trusses.

Solution: The Conjoined Twin Couplers are precision-engineered to overcome bracing interference on 50mmØ truss structures, enabling fixtures to be mounted exactly where needed. Featuring a uni-body design with a machined slot and M12 counter-sink bolt, the couplers facilitate fine positioning of lighting fixtures, projectors, and LED wall panels along the truss cords—avoiding cross members and braces.

Available in two load-rated variations:

-

Conjoined Twin 50mmØ Slimline Coupler (SWL 450kg) – ideal for heavy-duty rigging applications requiring maximum load capacity.

-

Conjoined Twin 50mmØ Easy Trigger Clamp (SWL 150kg) – designed for lighter fixtures where faster handling and adjustment are preferred.

Both versions meet the stringent quality standards expected from Global Truss accessories. Whether mounting heavy equipment or prioritising speed and convenience, these couplers offer a dependable, efficient solution for production professionals.

Arc Roof Structure

Brief: The F34P Truss Arc Roof (8.5m x 6.5m) is a certified modular roofing system designed to provide reliable structural cover for outdoor events. Constructed from F34P truss with 50mmØ x 3mm chords, it combines engineered strength with a visually distinctive curved design. Suitable for stages, Front of House areas, and event shelters, its modular design offers flexibility to fit certain existing spaces—with any alterations requiring engineer approval to ensure structural certification.

Solution: The F34P Truss Arc Roof delivers a professional-grade shelter solution for small to medium-scale outdoor events, including music festivals, pop-up activations, and community celebrations. Built for durability and engineered compliance, the arc structure enhances visual appeal without compromising strength. Supplied as a complete system or as custom-configured components, the modular design supports flexible setups while remaining practical for transport and storage. The F34P Truss Arc Roof is where certified structural reliability meets event-ready presentation.

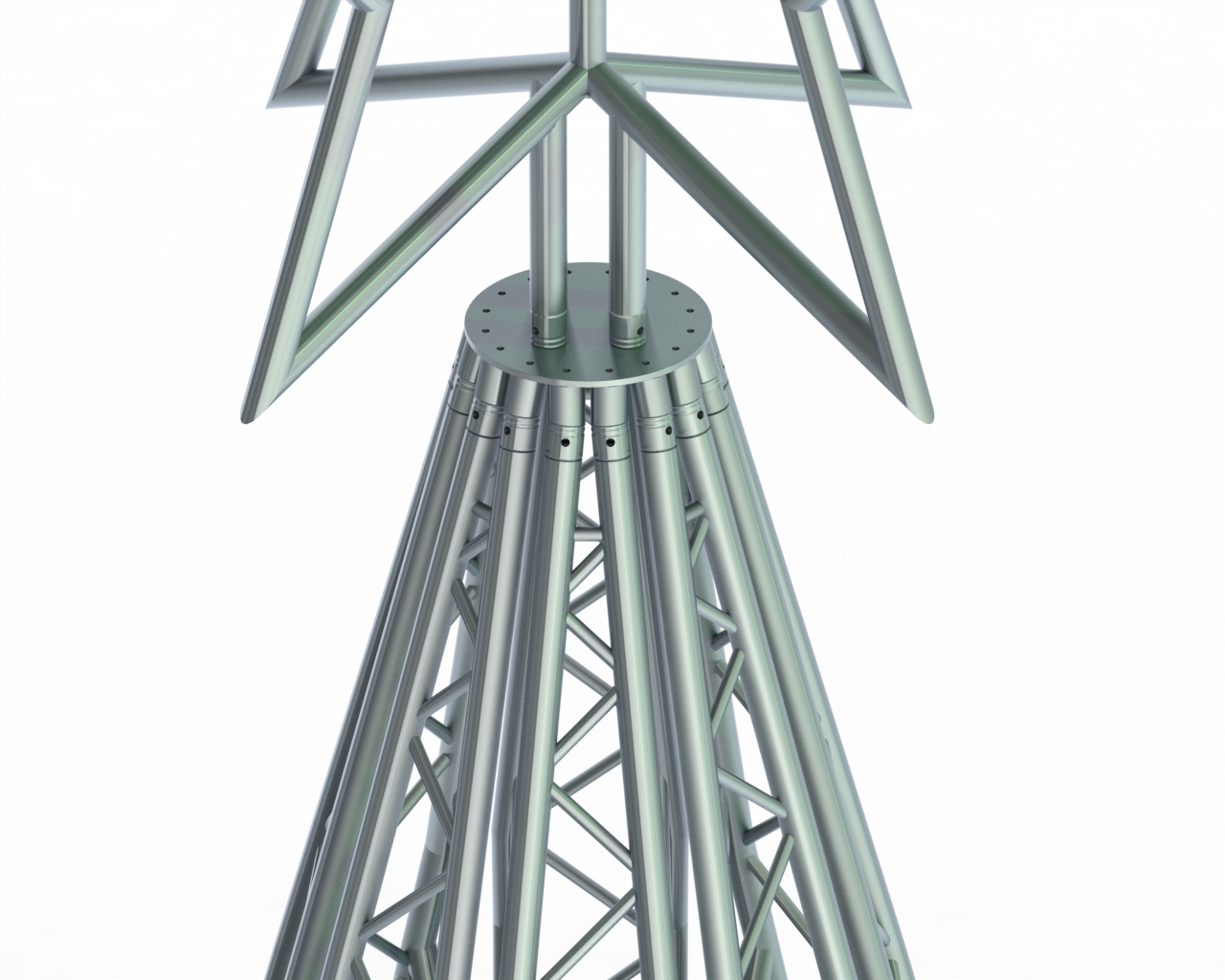

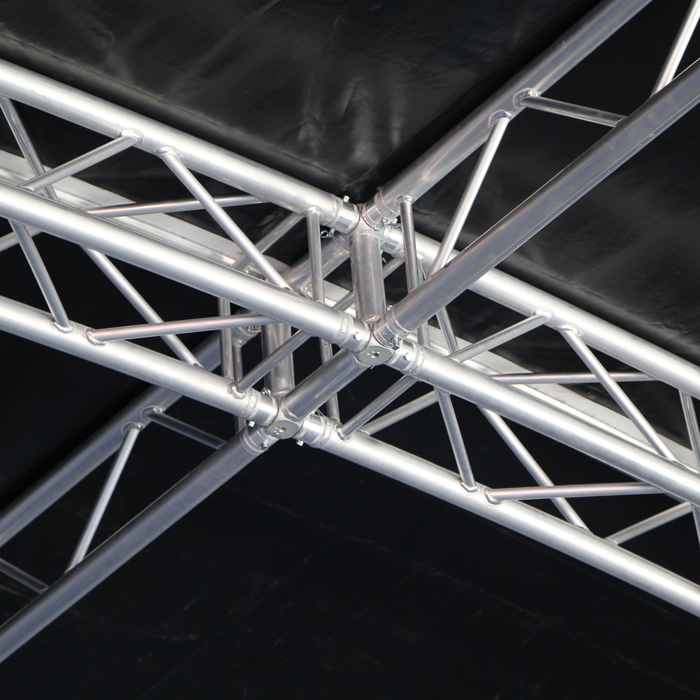

Baby Tower Structure

Brief: In live and studio television production, visual clarity and unobtrusive design are paramount—especially when camera movements are dynamic and wide-ranging. Traditional truss towers, while structurally sound, often disrupt the visual field when captured during panning shots. A major Australian broadcaster required a ground support structure for lighting and rigging that would not interfere with the camera’s line of sight or distract from the onscreen content.

Solution: Design Quintessence’s Baby Tower offered a refined solution. Unlike conventional truss columns, the Baby Tower was designed with round vertical columns, which made it visually discreet during camera pans and tracking shots. The unique circular profile didn’t catch the light or cast the same angular shadows as truss, meaning it often went unnoticed in frame. This subtle but effective design allowed the production team to maintain full rigging capability without compromising visual aesthetics.

Originally conceived with television applications in mind, the Baby Tower is a testament to the idea that form and function can coexist without distraction—meeting technical requirements while supporting the creative vision behind the scenes.

Ops Surround Kit

Brief: The Curtain Call Ops Surround Kit was developed to provide a versatile, portable drape system that offers elegant space separation and stage backdrop coverage for gala events, theatre productions, and large-scale ceremonies.

Solution: Curtain Call Ops Surround Kit – Portable, Adjustable Drapery System for Stage and Event Spaces

The Curtain Call Ops Surround Kit is a flexible and robust portable drape system designed to separate large areas and conceal unsightly stage backs with professional-quality velvet curtains. Featuring six telescopic posts adjustable from 1.0m to 1.5m in height, and five cross-bars extendable from 1.3m to 2.1m in depth, the system allows tailored configurations to fit specific stage and event space dimensions.

Equipped with sturdy steel base plates (450mm x 450mm x 6mm) and Curtain Call spigots, this kit ensures stability and secure assembly. It supports double curtain suspension, making it suitable for heavier drapes. Included velvet ops surround drapes provide a refined finish ideal for gala events, award ceremonies, theatre productions, and other sophisticated occasions.

Designed for efficiency, the Curtain Call Ops Surround Kit is compact and easily transportable with specially designed storage bags, enabling production teams to set up polished, elegant event environments quickly and reliably.

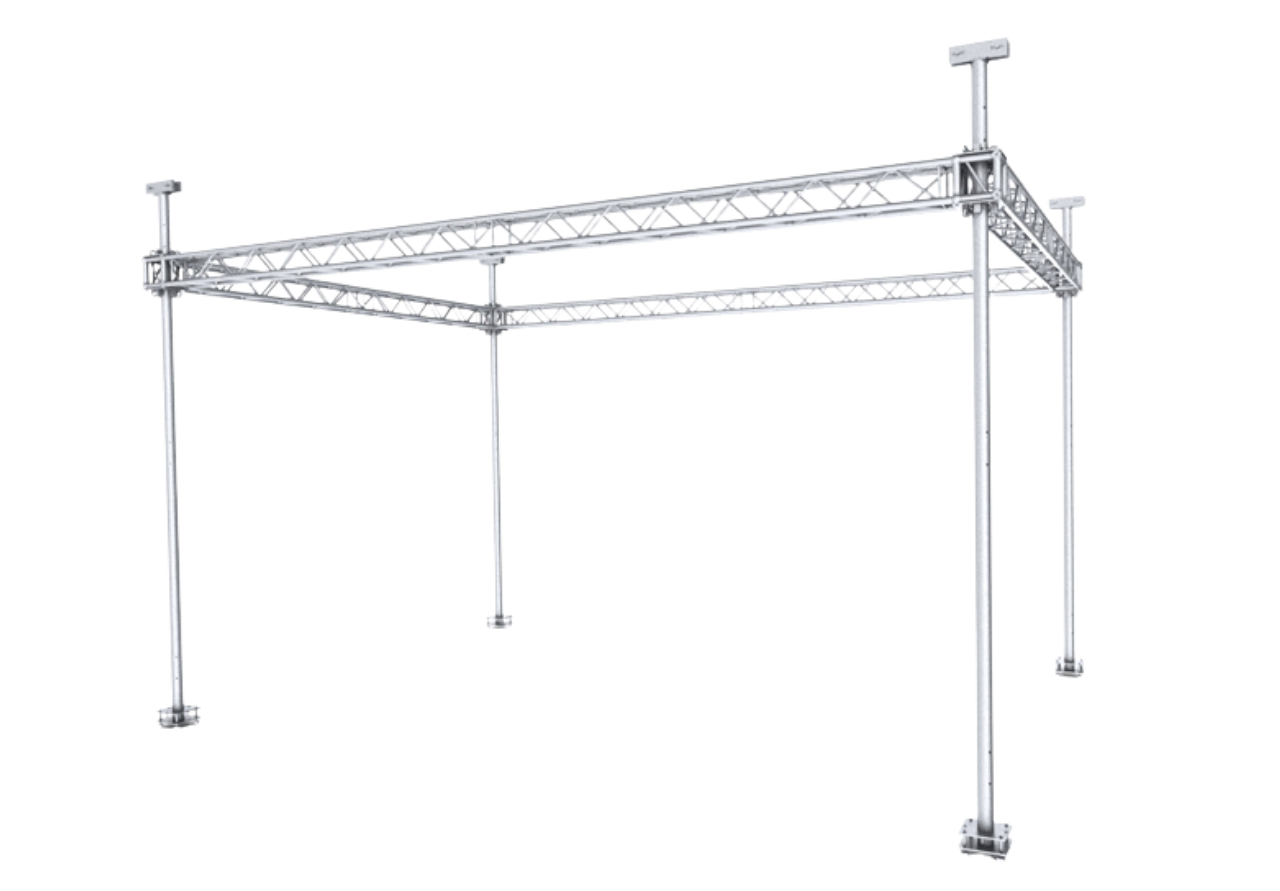

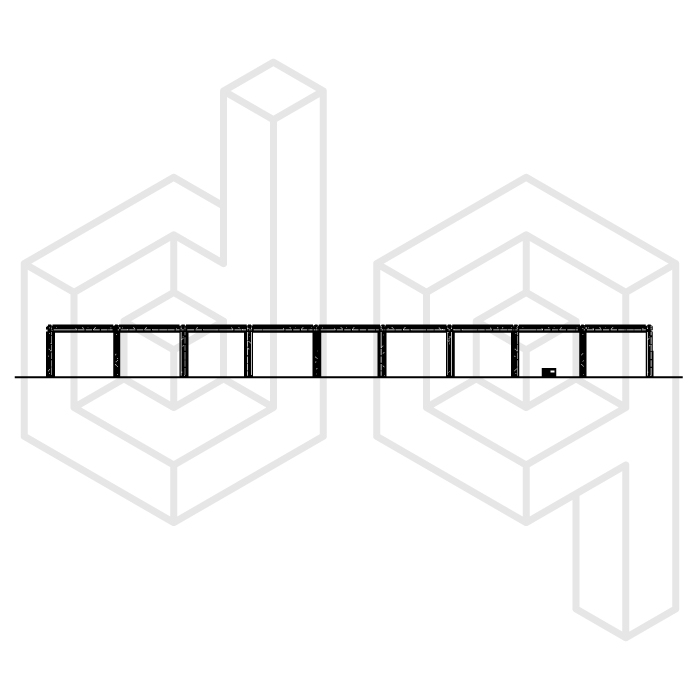

Emergency Relief Shelters

SKU: GT-FIELDHOSP

Design Quintessence’s Emergency Relief Shelters are modular, rapid-deploy structures designed to support healthcare facilities, emergency services, and disaster response operations.

Built with Global Truss components, each shelter offers a strong, scalable framework suitable for field hospitals, triage units, and isolation spaces. Engineered for flexibility, these systems can be deployed quickly and configured to suit a wide range of environments and requirements.

Features and Benefits

• Modular, expandable layout for scalable capacity

• Heavy-duty frame with rigging points for lighting, cabling, or HVAC

• Vinyl panel walls for privacy, separation, or noise control

• Suitable for both indoor and outdoor use

• Customised drawings and engineering documentation available

Trusted across Australia, DQ offers fast turnaround, local support, and high-quality solutions for emergency preparedness and response.

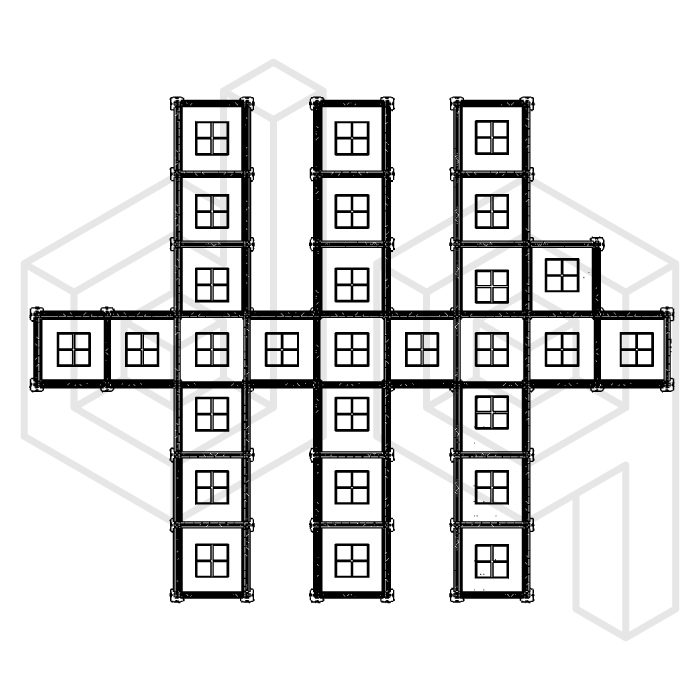

Modular Space Partitions

SKU: GT-CRWDCTRL-03

Developed in response to growing safety requirements and the need for adaptable space management, our team has designed a flexible, modular system to support temporary crowd control and space division.

Features and Benefits

• Fully modular design – easily reconfigurable to suit different layouts and control customer flow in aisles

• Heavy-duty construction – ideal for managing foot traffic in retail or event environments

• Vinyl panel walls – support distancing measures while maintaining customer service access

• Customisable to suit a wide range of locations and applications

This solution is built using standard components from the Design Quintessence Curtain Call range. Originally designed for room dividers and backdrops, the system also functions effectively as aisle barriers and allows for hanging signage or objects when required.

Truss Presentation Set

Brief: The Truss Presentation Set was created to meet the demand for stylish, professional-grade presentation solutions that integrate easily into event spaces.

Solution:Design Quintessence offers a range of exclusive, individually sold truss presentation solutions, designed for professional events, exhibitions, and corporate spaces:

-

Curved Truss Lectern (SKU: GT-F-LECT):

A unique F33 truss lectern with a clear acrylic top, integrated cable management, LED uplighter mount, adjustable feet, and a built-in signage frame (550mm x 800mm). Designed for professional presentations and branding display. -

F33 Truss Style Screen Stand (SKU: GT-F-SCRNSTD):

A stable, adjustable screen stand with six mounting positions, landscape/portrait options, and compatibility with TVs and display screens. Optional acrylic shelf and mobile base available for flexible event setups. -

A33-F44 Plasma/LCD Truss Mount Assembly (SKU: GT-F-PBA33-F44-C):

A discreet, low-profile mount for securing plasma and LCD screens directly to A33 and F44 truss structures.

Each product is sold separately and custom-designed by DQ to deliver professional functionality with a polished, truss-based aesthetic.

When off-the-shelf options fall short, our team at Design Quintessence develops tailored solutions to meet the specific demands of our industry. These purpose-built components often lead to entirely new products—creations that didn’t exist before but are now part of our exclusive range. For 30 years, DQ has delivered smart, effective design solutions to the event, production, theatrical and touring industries. Whether it's a custom truss centrepiece, unique rigging configuration, specialised road or flight case, or a custom colour finish, DQ has the capability and experience to meet your requirements.

If we don't have a solution, then a solution doesn't exist... yet!

Showcasing Creations: Custom Designs, Products & Ideas

Select a tab to explore projects, products and ideas.

Truss Skull

Brief: Can we build a skull from truss?

Solution: Here at DQ we believe truss can be used to build anything so of course the answer was “Yes!” This 9m tall truss skull was one of our most challenging custom truss designs as it took a while to get the form and “personality” of the skull right.Trepidation from factory staff in making and building such an unusual structure soon turned into excitement and pride when they completed the fabrication.

As with any custom designs, we used as many standard truss components as we could so that they could be used in other everyday applications (ensuring the production company achieves a much faster return on investment).

The skull structure has won an international award and been copied in countries as far afield as Mexico City.

Custom Guitar Truss

Brief: Build a large scale replica of Brian May’s guitar for a WA pro-am production of “We Will Rock You”

Solution: Scanning and tracing a CAD drawing of his actual guitar allowed us to create a design using custom and standard truss components that followed the outline of the actual guitar pretty closely.

With a guitarist sitting and playing inside the 8m long truss guitar whilst it is slowly lowers from the ceiling down onto stage ensures that the grand finale makes a lasting impression on all those who see the show.

Truss Christmas Tree

Brief: Design a large Christmas tree out of truss, to be erected in Darwin’s George Brown Botanical Gardens.

Solution: The 8.0m truss structure had to be built from standard components and easy to rig for its short-term installation. It also needed to withstand storms with winds up to 187 km/h in Darwin’s extreme weather.

The conical shape of the tree body was achieved using our new product, the GT F34 variable junction, which facilitates incremental connection of truss pieces from 0 to 25 degrees. To bring all the beams together, we designed a special linear truss with box configuration on the bottom and flat configuration on the top. This resulted in three unique angles converging at the top of the truss tree. To resolve this, we designed and fabricated a custom spigot adaptor that neutralised all spatial angles, allowing them to align with a single flat steel plate at the peak.

“The entire structure came together beautifully, without faults!” Colin West, managing director of Total Event Services exclaimed.

The truss tree was both robust and easy to rig, made possible by our expert design team. Thanks to streamlined manufacturing, all custom parts were delivered on time for the season.

Modular Access Ramp

Brief: Design Quintessence developed the Modular Access Ramp to deliver an Australian Standard compliant accessibility solution for stages, schools and event venues.

Solution: Modular Access Ramp – Engineered Accessibility Ramp for Wheelchair and Pedestrian Access

Developed over several years in response to industry demand, the Global Truss Modular Wheelchair Access Ramp by Design Quintessence offers a professional, fully engineered solution for accessibility to stages and elevated areas. Purpose-built for wheelchair and pedestrian access, this system meets Australian Standards and is designed specifically for event venues, schools and staging environments. With durable, modular construction, the ramp accommodates landing heights from 300mm to 900mm and provides a safe 1:14 incline for smooth, compliant access. Featuring a 1000mm wide ramp, curved and continuous handrails, tactile indicators and expanded landings for improved wheelchair manoeuvrability, the ramp system ensures safety and inclusivity. Compatible with standard stage decks and offering configurable left-turn, right-turn, and wraparound layouts, this ramp is ideal for festivals, theatres, schools, and venues requiring permanent or temporary accessibility solutions without compromising structural integrity.

Stage Car Ramp

Brief: To meet the demand for a heavy-duty, adjustable ramp solution, Design Quintessence engineered the Stage Car Ramp specifically for safe vehicle and equipment access on stages in event and production environments.

Solution: Stage Car Ramp – Heavy-Duty Vehicle and Equipment Access Ramp for Stages

The Stage Car Ramp (SKU GT-STG-CARAMP) is a robust, engineered ramp designed to provide safe and reliable vehicle and equipment access to stages and elevated areas. Constructed with a non-slip 17mm plywood top board and an aluminium entry ramp, it delivers excellent traction and stability for heavy loads.

Adjustable legs allow precise height adaptation to fit various stage elevations, making it highly versatile for both temporary and permanent staging setups. Engineered to withstand substantial weight, the Stage Car Ramp is ideal for theatres, festivals, exhibitions, and production venues requiring robust logistics solutions.

This ramp ensures compliance with safety standards while facilitating efficient load-in and load-out operations for vehicles and crew equipment.

Camera Riser Kit

Brief: The Global Truss Camera Riser Kit was developed to meet the need for a stable, professional-grade platform solution for tripod-mounted cameras at live events, festivals, and broadcast environments.

Solution: Global Truss Camera Riser Kit – Two-Tier Modular Camera Platform System

The Global Truss Camera Riser Kit is a purpose-built, two-tier riser system designed to provide elevated, stable camera positioning for professional filming and live production environments. Engineered to improve sightlines and bypass audience obstruction, the system separates the tripod from the operator on dual non-slip platforms, reducing accidental camera movement and ensuring steady, high-quality footage.

Featuring adjustable legs for flexible height configurations, the kit adapts to different venue layouts and filming requirements. The lower platform supports the tripod on a 1.55m x 1.05m stage deck with 800mmH legs, while the upper platform provides a 1.8m x 1.2m operator deck with 900mmH legs and under-deck storage clips to secure components during transport.

For logistics and storage, the kit includes two custom-designed dollies (left and right) to securely transport the system between locations. Durable, stable, and engineered for demanding environments, the Global Truss Camera Riser Kit is ideal for sporting events, concerts, festivals, and live broadcast productions where professional camera support is critical.

Ovation Motorised Screen Lift Case for 75" Display - Eleven Design

Brief:Eleven Design required a professional, road-ready case solution for transporting and presenting a 75” screen across various client sites and events. The case needed to protect the screen during transit while offering a clean, streamlined setup that aligned with their polished presentation style. A motorised lift was essential for ease of use and efficient setup in front-facing environments.

Solution: Design Quintessence provided a custom Ovation Motorised Screen Lift Case, tailored to the specific dimensions and handling needs of a 75” screen. The design featured heavy-duty hardware, durable construction, and a smooth motorised lift mechanism to raise the screen at the push of a button. Internal foam was precision-cut for secure placement, and the case included integrated cable access to allow for quick connectivity.

The result was a mobile presentation unit that combined protection, practicality, and professionalism in one refined package.

Dobson's Ozone Spectrophotometer Multi-Piece Road Case

SKU: DESIGNit-BOM-CASE

Brief: Design and build a case for a 50+ year old priceless atmospheric ozone measuring instrument and a range of accessories to safely ship it around the world.

Solution:The fact that only a handful of these instruments designed in 1924 are left operating across the world was not lost on us as we were creating a case design to protect what is an irreplaceable item.

This four piece case comprised a permanent pallet style base allowing forklift loading onto aeroplanes, a low base with detailed CNC foam fit out for the spectrophotometer, a lift-off body, separate lift-out accessory tray and a removable lid that doubles as a trolley when placed underneath for onsite manoeuvrability.

When we finished building the case it was loaded onto a plane the same week for the spectrophotometer’s next assignment in Antarctica.

TLX Custom Furniture & Tour Living Case

Brief: TLX needed a durable, all-in-one case solution to house a coffee machine and mini fridge for use during long production days while working on a show. The goal was to create a mobile hospitality setup that provided comfort and convenience backstage, without compromising on quality or portability.

Solution: Design Quintessence delivered a fully custom Ovation Case built to meet the demands of a busy production environment.

The case securely housed both appliances with reinforced compartments, integrated ventilation, and reliable access to power. Precision-cut foam ensured safe transport, and smart cable management kept the setup clean and efficient.

Compact, robust, and road-ready, the case has become an essential part of TLX’s production kit—keeping the crew fuelled and ready to perform.

Cladding Coupler

Brief:Developed in response to a project enquiry from the Australian Museum, the Cladding Coupler from Design Quintessence offers a versatile solution for mounting panels directly onto truss structures. Designed for public spaces and commercial environments, it enables fast, secure installation of various cladding materials—ideal for exhibitions, architectural applications, signage, and temporary barriers. The modular coupler uses integrated slots, M4 screw fixing points, or Velcro and adhesives to suit multiple mounting styles. Made to work with Global Truss systems, this purpose-built solution is now in stock and widely adopted.

Solution: The Design Quintessence Cladding Coupler is a multi-functional truss accessory designed to simplify cladding and panel mounting for Global Truss structures. Developed through extensive research and real-world testing, the coupler supports transparent acrylic panels, MDF boards, signage, and architectural panels using integrated slots, precision M4 screw points, or adhesive methods. Popular for truss climb prevention, exhibition cladding, set installations, and commercial signage, this innovative attachment was launched at Entech Show 2022 and has received strong market feedback. Engineered for strength and ease of use, the Cladding Coupler is now available from Design Quintessence.

Truss Extender

Brief: The Adjustable Truss Extender from Design Quintessence is engineered to simplify wall-mounting and structural spacing for aluminium truss systems. Specifically designed for F34 and F44P truss, this extender creates a secure connection point to walls or uneven surfaces, allowing truss structures to be installed safely in restricted or awkward spaces.

Manufactured from heavy-duty 6mm steel and featuring multiple bolt holes, it provides strong, stable support for truss installations in entertainment venues, stages, and commercial environments.

Solution: The Adjustable Truss Extender is a reliable mounting solution for attaching F34 and F44P aluminium truss systems to walls or other surfaces. By creating a precise gap between the truss and mounting surface, it allows essential clearance for cables and equipment while ensuring a clean, professional installation.

Made from 6mm steel plates and designed with multiple fixing points, this extender serves both as a wall-mount bracket and a structural leg extender for uneven ground. It’s ideal for tight spaces where direct truss mounting isn’t possible, supporting safe and efficient installations of lighting and AV equipment.

Twin Conjoined Coupler

Brief: The Conjoined Twin 50mmØ Coupler range from Design Quintessence solves one of the most common rigging challenges: precise fixture positioning obstructed by truss bracing. Designed for 50mm aluminium truss systems, this innovative coupler is available in two variations to suit different rigging needs: the Slimline Coupler (SWL 450kg) and the Easy Trigger Clamp (SWL 150kg). Manufactured from custom-machined aluminium extrusion, both options ensure accurate, secure fixture placement while maintaining compatibility with Global Truss systems, including F34, F44P, and 5 Chord Trusses.

Solution: The Conjoined Twin Couplers are precision-engineered to overcome bracing interference on 50mmØ truss structures, enabling fixtures to be mounted exactly where needed. Featuring a uni-body design with a machined slot and M12 counter-sink bolt, the couplers facilitate fine positioning of lighting fixtures, projectors, and LED wall panels along the truss cords—avoiding cross members and braces.

Available in two load-rated variations:

-

Conjoined Twin 50mmØ Slimline Coupler (SWL 450kg) – ideal for heavy-duty rigging applications requiring maximum load capacity.

-

Conjoined Twin 50mmØ Easy Trigger Clamp (SWL 150kg) – designed for lighter fixtures where faster handling and adjustment are preferred.

Both versions meet the stringent quality standards expected from Global Truss accessories. Whether mounting heavy equipment or prioritising speed and convenience, these couplers offer a dependable, efficient solution for production professionals.

Arc Roof Structure

Brief: The F34P Truss Arc Roof (8.5m x 6.5m) is a certified modular roofing system designed to provide reliable structural cover for outdoor events. Constructed from F34P truss with 50mmØ x 3mm chords, it combines engineered strength with a visually distinctive curved design. Suitable for stages, Front of House areas, and event shelters, its modular design offers flexibility to fit certain existing spaces—with any alterations requiring engineer approval to ensure structural certification.

Solution: The F34P Truss Arc Roof delivers a professional-grade shelter solution for small to medium-scale outdoor events, including music festivals, pop-up activations, and community celebrations. Built for durability and engineered compliance, the arc structure enhances visual appeal without compromising strength. Supplied as a complete system or as custom-configured components, the modular design supports flexible setups while remaining practical for transport and storage. The F34P Truss Arc Roof is where certified structural reliability meets event-ready presentation.

Baby Tower Structure

Brief: In live and studio television production, visual clarity and unobtrusive design are paramount—especially when camera movements are dynamic and wide-ranging. Traditional truss towers, while structurally sound, often disrupt the visual field when captured during panning shots. A major Australian broadcaster required a ground support structure for lighting and rigging that would not interfere with the camera’s line of sight or distract from the onscreen content.

Solution: Design Quintessence’s Baby Tower offered a refined solution. Unlike conventional truss columns, the Baby Tower was designed with round vertical columns, which made it visually discreet during camera pans and tracking shots. The unique circular profile didn’t catch the light or cast the same angular shadows as truss, meaning it often went unnoticed in frame. This subtle but effective design allowed the production team to maintain full rigging capability without compromising visual aesthetics.

Originally conceived with television applications in mind, the Baby Tower is a testament to the idea that form and function can coexist without distraction—meeting technical requirements while supporting the creative vision behind the scenes.

Ops Surround Kit

Brief: The Curtain Call Ops Surround Kit was developed to provide a versatile, portable drape system that offers elegant space separation and stage backdrop coverage for gala events, theatre productions, and large-scale ceremonies.

Solution: Curtain Call Ops Surround Kit – Portable, Adjustable Drapery System for Stage and Event Spaces

The Curtain Call Ops Surround Kit is a flexible and robust portable drape system designed to separate large areas and conceal unsightly stage backs with professional-quality velvet curtains. Featuring six telescopic posts adjustable from 1.0m to 1.5m in height, and five cross-bars extendable from 1.3m to 2.1m in depth, the system allows tailored configurations to fit specific stage and event space dimensions.

Equipped with sturdy steel base plates (450mm x 450mm x 6mm) and Curtain Call spigots, this kit ensures stability and secure assembly. It supports double curtain suspension, making it suitable for heavier drapes. Included velvet ops surround drapes provide a refined finish ideal for gala events, award ceremonies, theatre productions, and other sophisticated occasions.

Designed for efficiency, the Curtain Call Ops Surround Kit is compact and easily transportable with specially designed storage bags, enabling production teams to set up polished, elegant event environments quickly and reliably.

Emergency Relief Shelters

SKU: GT-FIELDHOSP

Design Quintessence’s Emergency Relief Shelters are modular, rapid-deploy structures designed to support healthcare facilities, emergency services, and disaster response operations.

Built with Global Truss components, each shelter offers a strong, scalable framework suitable for field hospitals, triage units, and isolation spaces. Engineered for flexibility, these systems can be deployed quickly and configured to suit a wide range of environments and requirements.

Features and Benefits

• Modular, expandable layout for scalable capacity

• Heavy-duty frame with rigging points for lighting, cabling, or HVAC

• Vinyl panel walls for privacy, separation, or noise control

• Suitable for both indoor and outdoor use

• Customised drawings and engineering documentation available

Trusted across Australia, DQ offers fast turnaround, local support, and high-quality solutions for emergency preparedness and response.

Modular Space Partitions

SKU: GT-CRWDCTRL-03

Developed in response to growing safety requirements and the need for adaptable space management, our team has designed a flexible, modular system to support temporary crowd control and space division.

Features and Benefits

• Fully modular design – easily reconfigurable to suit different layouts and control customer flow in aisles

• Heavy-duty construction – ideal for managing foot traffic in retail or event environments

• Vinyl panel walls – support distancing measures while maintaining customer service access

• Customisable to suit a wide range of locations and applications

This solution is built using standard components from the Design Quintessence Curtain Call range. Originally designed for room dividers and backdrops, the system also functions effectively as aisle barriers and allows for hanging signage or objects when required.

Truss Presentation Set

Brief: The Truss Presentation Set was created to meet the demand for stylish, professional-grade presentation solutions that integrate easily into event spaces.

Solution:Design Quintessence offers a range of exclusive, individually sold truss presentation solutions, designed for professional events, exhibitions, and corporate spaces:

-

Curved Truss Lectern (SKU: GT-F-LECT):

A unique F33 truss lectern with a clear acrylic top, integrated cable management, LED uplighter mount, adjustable feet, and a built-in signage frame (550mm x 800mm). Designed for professional presentations and branding display. -

F33 Truss Style Screen Stand (SKU: GT-F-SCRNSTD):

A stable, adjustable screen stand with six mounting positions, landscape/portrait options, and compatibility with TVs and display screens. Optional acrylic shelf and mobile base available for flexible event setups. -

A33-F44 Plasma/LCD Truss Mount Assembly (SKU: GT-F-PBA33-F44-C):

A discreet, low-profile mount for securing plasma and LCD screens directly to A33 and F44 truss structures.

Each product is sold separately and custom-designed by DQ to deliver professional functionality with a polished, truss-based aesthetic.