In the dynamic world of event production, Design Quintessence has been quick to pick up on the rising popularity of Global Pre-Rig Truss. We’ve observed a noticeable uptick in customers opting for this tried-and-true product, with notable examples like EI Productions being one of the first in Australia to try it and they haven’t looked back since. They recently enjoying …

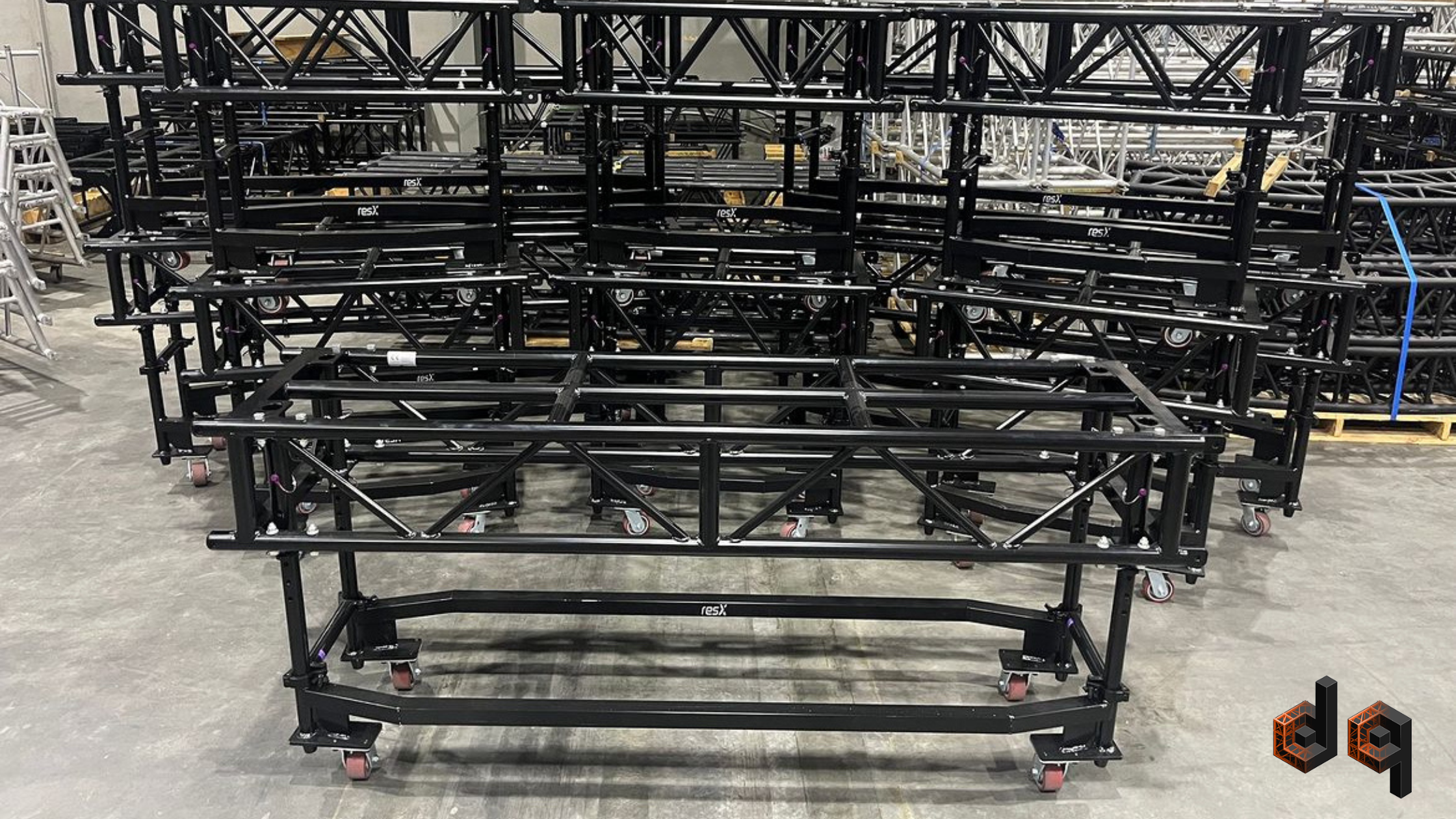

Global Pre-Rig Truss Solutions Propels ResX Success

An increasing number of companies are discovering the remarkable advantages of our Global Pre-rig truss, and its popularity is soaring. Design Quintessence has stood as a reliable supplier for Resolution X for an extensive period. Recently, our collaboration involved tailoring pre-rig trusses precisely to suit their Aussie trucks, amplifying their touring capabilities to effortlessly maneuver through venues across the country! …

The Journey to Paris with Monet

In recent years, the use of immersive technologies has surged in popularity due to its capacity to deliver an interactive experience, captivating users through touch, sound, and visual elements. It continues to captivate individuals due to the nature of its fully engaging experience and the flexibility in its application. The magic of immersive technologies lies in the power to transport …

Caltex Stands Tall at Diesel Dirt and Turf Expo 2023 with F44P Global Truss

The highly anticipated Diesel Dirt & Turf Expo was back for its annual exhibition on 21-23 April 2023 with quite a number of guests and companies attending. The expo began in 2015 gaining popularity within the construction industry as it allowed a variety of industry contractors and suppliers to promote and launch new products in front of a large audience. …

Revolution Staging uniting Melbourne’s resilient music artists at SQUARE UP

During the first quarter of 2021, The Operatives helped celebrate some of Melbourne’s resilient artists, and live music’s unique ability to connect, heal, and unite. Debuting the first of its kind, SQUARE UP, the event saw musicians, DJs and visual artists sharing a custom-built stage in a live collaborative setting built in one of Melbourne’s unique theatres, Forum Melbourne. The …