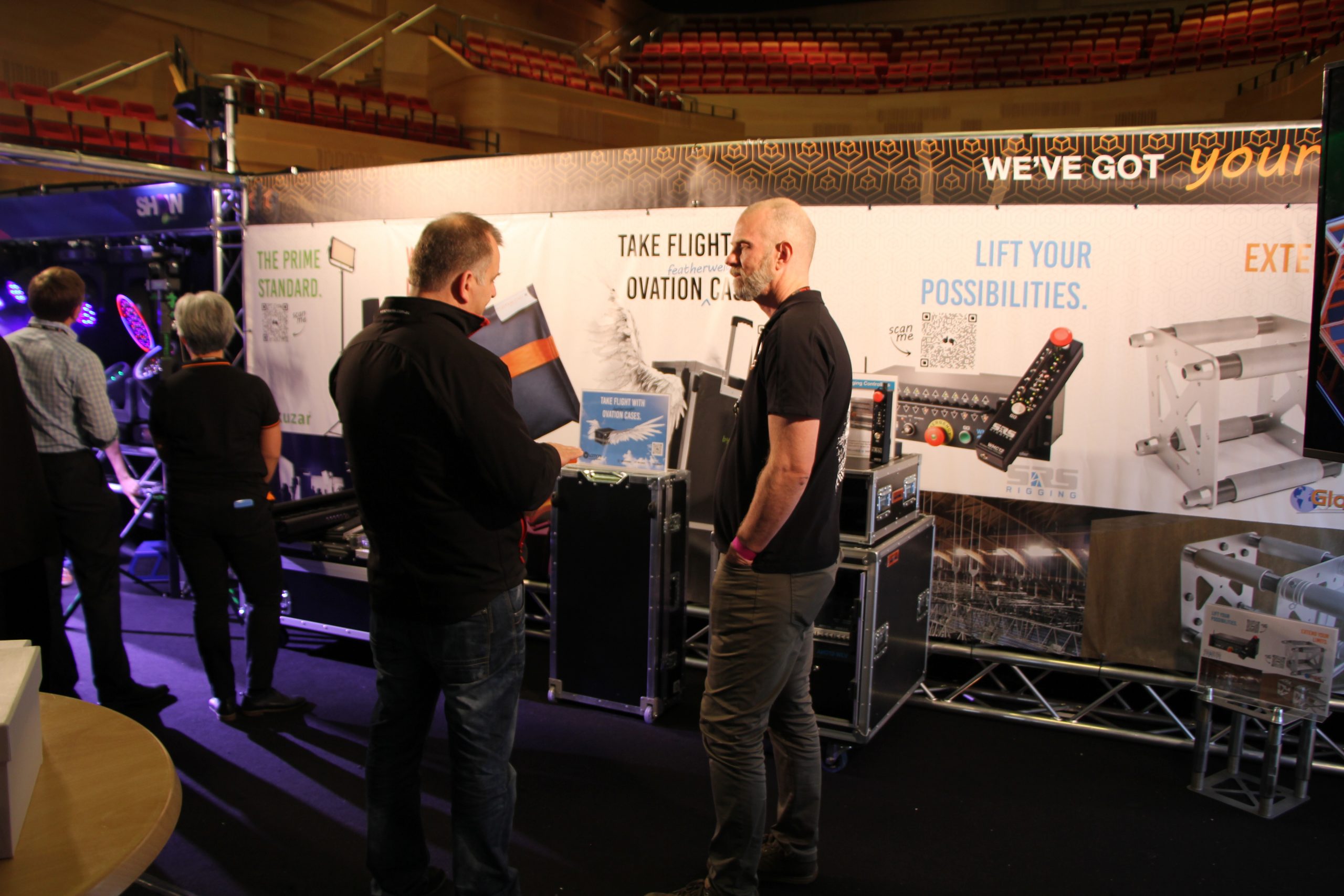

After more than two (2) years since the last Entech Roadshow, the return of the event this 2022 has been highly anticipated. At Design Quintessence, we were excited to present a range of new products that were developed in-house such as the cladding coupler, truss extender plate, and the long-awaited range of Featherweight Cases. We are thrilled to present that it was a success after receiving multiple enquires about the new range of Featherweight Cases.

Compared to our standard Ovation Cases, our new Featherweight Cases are made with a revolutionary 100% recyclable composite structure. It is manufactured with panels created with polypropylene fibres and a honeycomb design, in contrast to the high-quality birch plywood of Ovation Cases. The honeycomb design has multiple benefits in which it ensures the case is lightweight while maintaining its durability. It also increases its resistance to impacts caused by chemicals, humidity, weather and liquids.

Another added benefit to our Featherweight Cases is its reduction of weight by 30%-40%. It is 80% lighter than the typical plywood, making it the best solution for those who want to travel with their equipment but are restricted by the policies of airlines. With our new cases, it is more cost-effective as it is cheaper to bring the case in the aeroplane compared to having it shipped.

The new materials, as previously mentioned, is 100% recyclable as fewer resources were used to produce the panels. Materials such as glass fibres were not used in the production of the panels, making it eco-friendly and sustainable. Moreover, it ensures a longer lifespan which reduces the need for replacements.

As an in-house design and manufacturing company, all our cases (including the new Featherweight Cases!) are manufactured in our Sydney manufacturing facilities. We can design Featherweight cases that are custom-made to order to provide our customers with bespoke solutions that could accommodate any unique design feature they would like.

Contact us and enquire now!