ROPE ACCESS AND RIGGING

Rope access technicians work in a wide range of industries that require specialised access solutions for working at heights or in challenging environments. Some of the industries where rope access technicians are commonly employed include:

- Construction

- Maintenance and Facilities Management

- Oil and Gas

- Wind Energy

- Power Generation

- Telecommunications and Broadcasting

- Mining and Quarrying

- Infrastructure and Civil Engineering

- Film & TV, Live Entertainment and Productions

These industries are just a sampling of the diverse sectors where rope access technicians are in demand. The versatility and efficiency of rope access techniques make them valuable across numerous industries that require safe and effective access to elevated or challenging work areas.

There are several examples of access solutions commonly used by rope access technicians. These access solutions vary depending on the specific work environment, height, and nature of the task.

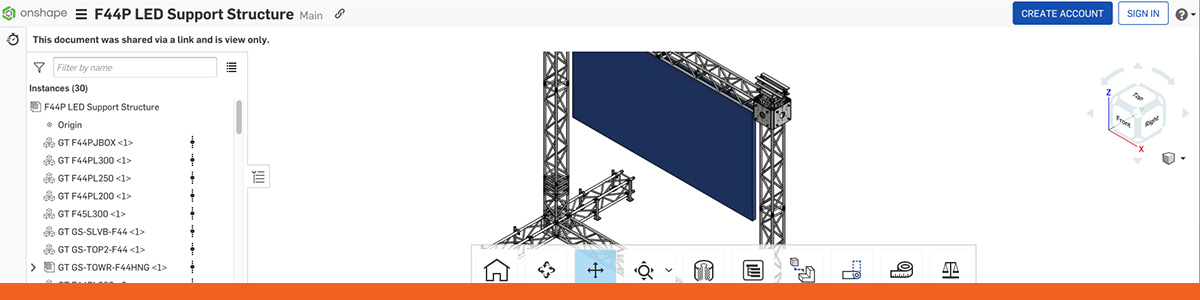

Design Quintessence carries an extensive range of modular aluminium truss components and systems across its four Australian warehouses; Sydney, Melbourne, Brisbane and Perth. Global Truss provides a combinations of versatility, strength and portability and can allow for temporary or permanent access solutions for rope access and rigging technicians as it can be adapted to fit different shapes and sizes of structures that can provide secure access to various levels or areas.

Rope access and rigging technicians are often involved in construction projects, working on high-rise buildings, and other structures. Temporary or permanent structures can be erected to provide spacious safe and stable working areas by creating elevated platforms for difficult-to-reach areas. This will help ensure that rope access and rigging technicians can access their work locations securely, helping minimise the risk of falls, accidents or injuries.

Industrial Rope Access can also consist of anchor points, ropes, and associated equipment designed for rope access work. This allows technicians to descend, ascend and move horizontally along ropes while performing tasks.

Temporary or permanent access solutions provide a safer, more efficient, and controlled means of accessing work areas for rope access and rigging technicians. DQ have the ability to work alongside well-respected engineers to collaborate on a variety of projects and structures.

DESIGN

Leading technology, software and on-site measurement to ensure the perfect fit and maximum protection and minimise your downtime.

In-house CAD/CAM

We use SolidWorks and CAMWorks, industry’s best software in-house. Preparing complete 3D models leaves no unknown aspects before the case is ready to be manufactured. Ply and foam pieces are precision machined for every custom case using CNC router based on the finalised design.

Creative Solutions

Having high-quality equipment and structures shouldn’t compromise the aesthetics and the possibilities you can do with it. Our creative team can customise and tailor our products to you, or even conceptualise your ideas into a reality.

On-site Measuring

Our team of designers are happy to visit you on sit to measure your equipment so you don’t need to move the equipment without protection. A non-disclosure agreement can be signed to keep any sensitive information secure in case the measured equipment is in development stages.

BRANDING

Promote your brand whether you’re on the move, seeing customers or displaying equipment.

Branding

Using our precision CAD/CAM facilities, we are able to brand your cases with your company logo. In addition to branding, engraving can be used for marking the contents of a case.

Custom Solutions

Collaborate with our creative designers to customise your next road case or truss structure. You could make a bold statement when presenting your equipment in colour, style and look with various options available to you.

Personalisation

Our bespoke customised road case labels branded with your logo and contact details are ideal for logistical information to help enhance your brand presence and manage your equipment better in full digital colour or black and white.

QUALITY

Built with the highest grade quality materials, our quality is guaranteed.

Safety

Safety is an everyday focus for Design Quintessence and we make sure that all our structural products are independently certified. We engage structural engineering consultants regularly for various projects across the country. We have taken initiatives such as our rigging workshops to open up the conversations in the staging industry and support other initiatives where we can. Our pursuit of safe products and their safe use is unfaltering.

High-quality materials

Produced with premium aluminium and created to have the highest possible quality, Global Truss products are reliable and provides the rigging backbone of the projection surfaces and screens, projection equipment and sound gear for many installations. Ensuring your safety, it is tested by TÜV Nord to certify its state and quality.