What it is about the Ovation brand that sets the standard for your protective case solution?

A manufacturing facility that produces premium portable cases should be equipped with the most sophisticated technology paired with high-quality materials used to fabricate and compliment the reputation the Ovation Case brand carries and our clients deserve.

#DESIGNit #CREATEit #PROTECTit

“I have looked at cases produced by many of the premium case manufacturers around the world, have even visited their factories, and I can proudly claim the fully Australian-made Ovation brand is equal to the world’s best.”

DESIGNit

A strong design ethic requires a powerful 3D CAD software programme that Design

Quintessence has heavily invested in since starting our manufacturing facility in 2014.

SolidWorks is one of the world’s leading 3D Design and Manufacturing CAD platforms allowing our in-house designers to conceptualise innovative solutions that simply work for you.

DQ is constantly striving to improve our CAD methodology. We also continuously review how the latest developments in CAD software can assist us in refining the design process even further.

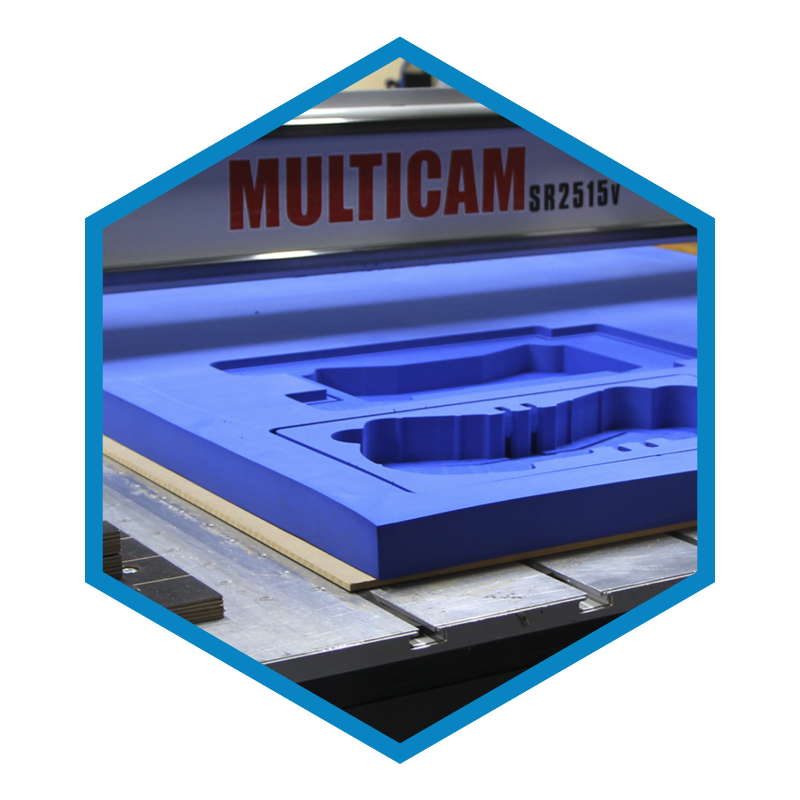

CREATEit

Our Sydney-based manufacturing facilities invest in the latest and most sophisticated technological manufacturing tools and equipment to deliver you premium quality in-house case builds.

We want to ensure our staff are well-equipped with the most advanced technology and equipment to aid in producing the best protective solution for your valuable equipment.

PROTECTit

From design to delivery, our experienced logistical staff will use the most appropriate delivery method to get your order to you safely and securely.

HARDWARE & MATERIALS

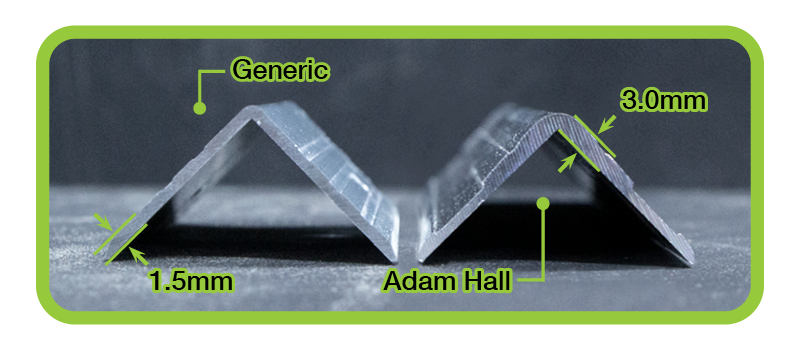

A well-built flight case should provide you with long-lasting equipment protection, so we have sourced a globally respected brand from Germany to supply most of our road case hardware.

Adam Hall is a pioneer of case components with over 40 years of experience producing high-quality, robust case fittings.

PLYWOOD CONSTRUCTION

We source laminated Birch Plywood from Scandinavia and the Baltic States, recognised as the best in the

world.

The Scandinavian Birch ply comprises dense layers laminated with high-performance and DIN-certified

(DIN EN 204) “D4” grade glue. It is double-laminated with a durable ABS plastic laminate on the

underside.

The plywood has optimum density with maximum stability and moisture resistance while the outer laminate

provides great resistance to damage and good camouflage of scratches and abrasions.

Below are just a handful of case elements we are proud to provide you with every case build:

ALUMINIUM EDGE EXTRUSION

LID STAYS

BUTTERFLY LATCHES

RIVETS

BALL CORNERS

CASTOR BACKING PLATES

CASTORS

YOUR OWN BRANDING

Be recognised and stay organised.

All Ovation cases are supplied with an Adam Hall tour label dish designed to house 178x127mm case labels.

We are able to provide custom branded tour labels to suit, along with full custom logo engraving on the case ply to create a bold, professional image of your business.