The LED screen is up, the gig is on track, when suddenly the event manager asks if it can be a little bit bigger. Sure, why not, it’s just a few more panels. A quick calculation of the new load and we’ll just add another hoist in the middle because we were already at the limit of the two hoists on the hang.

But wait, have you considered the load distribution? If two 500kg hoists give you 1000kg of lifting capacity, can three 500kg hoists give you 1500kg?

Let’s take a closer look.

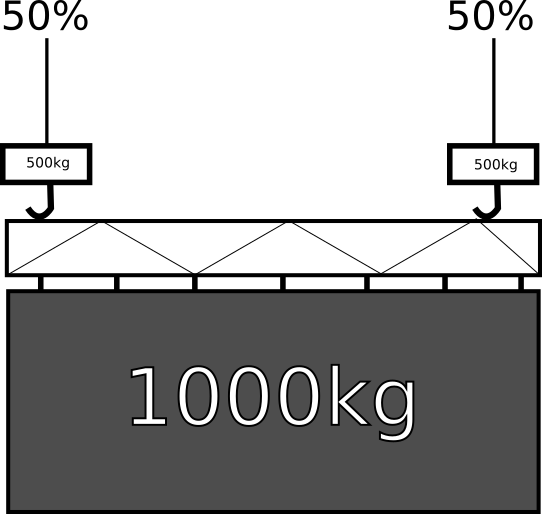

The starting scenario looks like this:

With 2 points supporting the load symmetrically, and a Uniformly Distributed Load, each hoist is going to see half the total load. (Note: this is only for Uniformly Distributed Loads, non-symmetrical point loads need closer attention, preferably by an engineer. The load includes the screen and all rigging hardware and truss up to the motor attachment points)

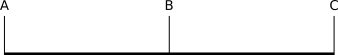

So, when the event manager asks for another few rows of screen, let’s say 200kg extra, the load is going to be 1200kg total (including all rigging equipment up to the motors) and each hoist will see 600kg. If the hoists are only rated for 500kg WLL then we cannot hang the extra panels. So, surely adding another 500kg hoist will solve that problem, right? Three times 500kg is 1500kg and that

brings us back inside the limit. Problem solved…or is it?

Figure 2: 1000 kg must include weight of all rigging up to motor hooks

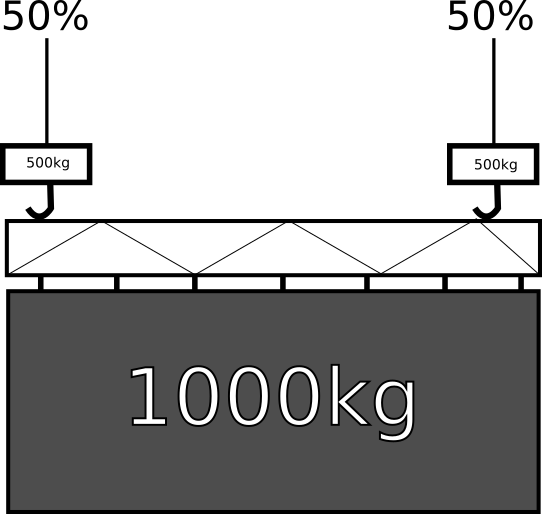

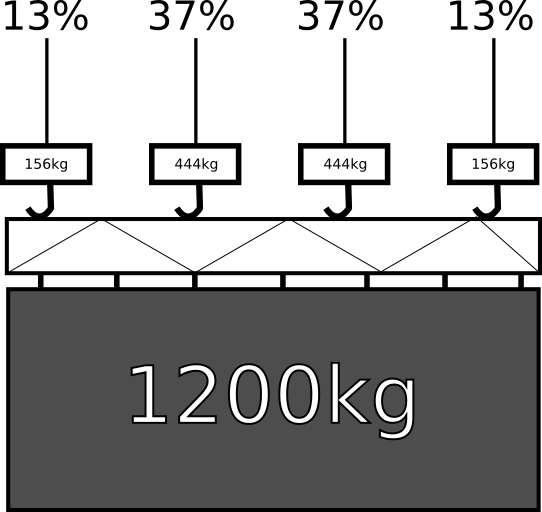

It’s not intuitive, but the load distribution when we move past 2-point hangs is no longer an easily determined split. In a 3-point hang, instead of each hoist seeing the same load, the centre point sees approximately 62% of the total load while the outer points approximately 19% each. The engineering calculations are complex, but more importantly the resulting distributions are theoretical; requiring load monitoring equipment to ensure the distribution is achieved in practice:

Figure 3: 1000 kg must include weight of all rigging up to motor hooks

Looking back to figure 2 we see that a 500kg hoist in the middle position is going to be overloaded by approximately 244kg.

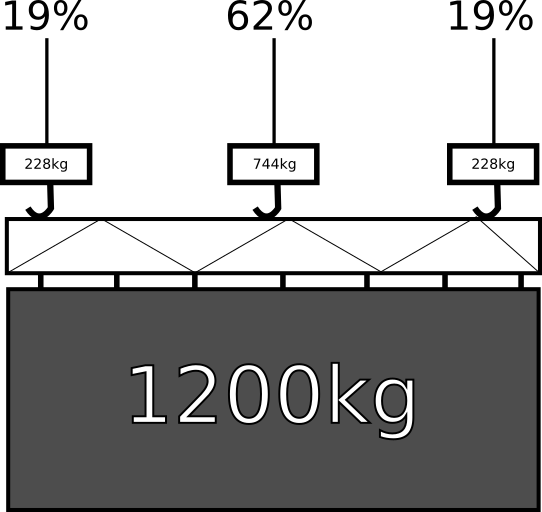

What if we used four points instead?

Figure 4: 1000 kg must include weight of all rigging up to motor hooks

The more points that we add to suspend a Uniformly Distributed Load, the smaller the difference between them. With four points our maximum hoist load is 444kg which keeps us within our hoist capacity and improves the level of redundancy against failure of the rigging system.

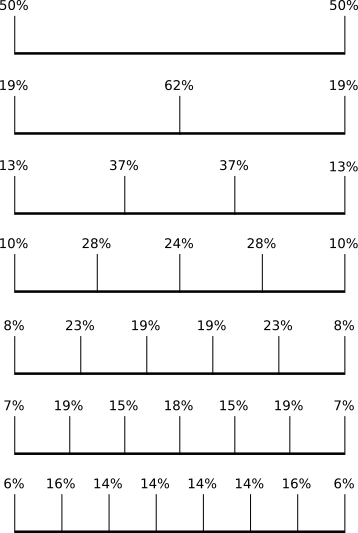

The following chart shows a range of multi-point hang scenarios for Uniformly Distributed Loads.

Figure 5: 1000 kg must include weight of all rigging up to motor hooks

By referring to this chart we can calculate either the required capacity of each point in a multi-point hang, or we can calculate the maximum load for a given set of points and their load capacity.

We’ve already seen how to calculate the required capacity for each point above, so we’ll now look at calculating a maximum load.

If we consider the 3-point hang again, let’s assume that we have the same three 500kg hoists to work with. If you only had those three hoists, or the available rigging points above only allow three points in total, how much can we put on the truss and remain within the lifting capacity of those hoists?

The calculation is as follows. Divide the capacity of the hoist by the highest percentage from the chart in figure 5 for that layout.

For a 3 point hang we get the following:

500kg WLL / 0.62 = 806kg total UDL load allowable

That alone should be a significant warning! Your maximum load has dropped when you added a third hoist.

If we look at 4 points now:

500kg WLL / 0.37 = 1351kg total UDL load allowable

That’s the increased capacity that we were looking for.

There are some points that should be considered about these calculations.

These engineering calculations are theoretical. In practice, hoists with higher loading run slower and getting the hoists to all be at exactly the same height and each with the theoretical load is almost impossible to achieve.

In summary, the load distribution chart applies only to Uniformly Distributed Loads.

The chart should only be used as a guide. At any time that your hoists are going to be lifting at or near their maximum capacity you should have an engineer check your calculations. We strongly recommend use of a load monitoring system and a load lifting plan to ensure that the capacity of the rigging system is not exceeded.