Inspection Schedules – When and by who?

We’ll start with the inspection schedule. In Australia we don’t have a specific aluminium truss standard that covers entertainment truss as we use it. What we can do is look to the Australian Workplace Health and Safety legislation and some comparable Australian Standards for rigging and lifting equipment.

It’s not a huge leap to say that entertainment truss is very similar to lifting beams used in the construction industry. If we look at AS 4991 for Lifting beams it suggests that lifting devices shall be inspected by a competent person at intervals specified by the manufacturer or by the competent person, but it doesn’t specify a timeframe. Most of your other rigging equipment e.g. shackles, hoists etc, have a 12-month timeframe for inspection and so it’s safe to say that a full inspection every 12 months is a suitable choice for your truss also.

But who is a competent person? The Australian Standard for Chain Slings says:

“A person having practical and theoretical knowledge and relevant experience, sufficient to enable that person to detect and evaluate defects and weaknesses that may affect the intended performance of the equipment. In court may be called upon to explain your level of competence. Often a Dogger, Rigger or Height Safety Trained individual.”

That also seems like a useful definition for our purpose. The competent person should be someone who knows the equipment and is able to identify issues that might cause problems.

There are two types of inspection that should be carried out on all lifting equipment.

In-Service inspections

Periodic Inspections

Inspection Criteria

General Inspection Items

- Check that identification sticker (Manufacturer, date of production and truss type) is attached

- Check welds for cracks or incomplete weld seams. Note that the weld on diagonal bracing tubes is not always required to go all the way around. This could vary between manufacturers so check with them to be sure.

- Check for any welds that have been worn down more than 10% of the raised height of the weld

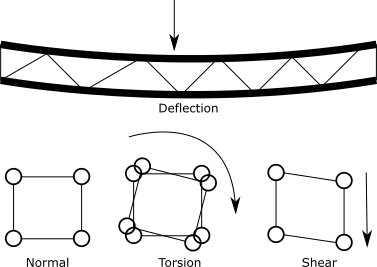

- Permanent deformation of any truss elements (main chords, braces, connections/coupler sockets). The truss should be checked for deformation, torsion (twisted truss) and shear deformation. A simple test is to place the truss on a flat floor or bench and check if it rocks back and forth.

- Corrosion

Main Chords

- Dents, scratches, or other damage that is deeper than 1mm and more than 10mm long

- Dents, scratches, or wear that reduces the cross-sectional area by more than 10%

- Holes in the main chord

- Misalignment of the chords and the connections so that they require force to join to another piece of truss

- Dents or deformation of the main chord to an oval shape

- Bent sections of the main chord more than 5 degrees off the straight line of the chord

Braces

The following criteria for the diagonal braces indicate that the truss should be discarded.

- Dents, scratches, or other damage that is deeper than 0.5mm and more than 10mm long

- Dents, scratches, or wear that reduces the cross-sectional area by more than 10%

- Holes in the brace

- Bent sections of the brace tube more than 5 degrees off the straight line

Connections

The following criteria for the couplers indicate that the truss should be discarded.

- Deflection of the couplers by more than 5 degrees

- Ovalisation and/or deformation of the pin/bolt holes in the conical coupler or the socket by more than 10%

- Scratches, hammer marks or other damage on the coupler that is more than 2mm deep and 10mm or more long.

Truss Pins

Truss pins undergo significant impact and wear when they are inserted and removed. The pins will wear out and should be discarded if they meet any of the following criteria.

- Bent pins indicate that they have been overloaded and they should be discarded

- Increase in diameter of more than 10%

- Burrs or mushrooming of the head and narrow end of the pin.

- Sharp edges or scratches on the surface of the pin

- Corrosion

Repairs

Truss is an engineered item and therefore repairs should be approached with extreme caution. Repairs should only be carried out by the manufacturer or a suitably qualified person. The repairer should then certify the truss before use. As a rule, once the truss is repaired it is unlikely to be capable of its original load ratings and it would be better to remove it from service and replace it.

Proper disposal

Simply marking the truss with tape to indicate that it should not be used is not recommended. It’s very easy to remove that tape and then it may no longer be easy to identify that the truss is unsafe. The best practice is to permanently render the truss inoperable by cutting it up with a grinder or taking it straight to a metal recycler for destruction (and maybe put the proceeds towards some beer to alleviate the pain).

Cleaning

Dirt and the like can be cleaned with water quite easily, but care should be taken with cleaning products to ensure that they are safe for use with aluminium. At no time should acids be used.

Summary

The discard criteria in this guide are not intended to be hard and fast rules, but guidelines. If you are unsure if a piece of truss is unsafe, do not use it. Always refer to your specific manufacturers guidelines if you are in doubt.