Sometimes, an idea is so simple that you wonder how nobody has thought of it before. One such idea appeared in 2021 in the staging and lighting market.

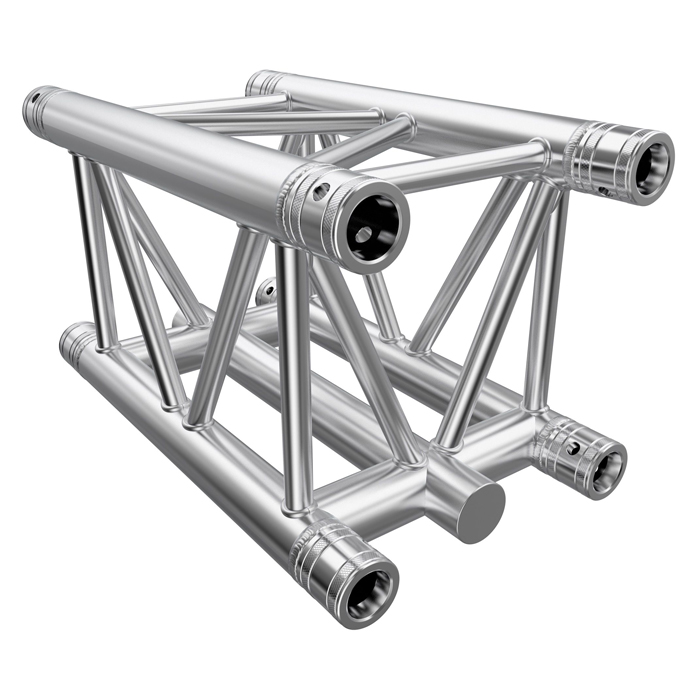

Modular Aluminium trusses are an inevitable part of any production. You will see them hanging over any event stage, carrying an army of lights, blinds, screens and projectors. Almost in every case, you want these types of equipment to hang centred to the truss; whether it’s for load balance, geometrical alignment, safety, or simply for their looks, they usually need to be centred across the chords. The riggers follow multiple techniques using slings and safety wires to achieve this goal by “hanging” the devices in the middle and effectively distributing the loads among all truss chords.

While solving the problem significantly, it has its caveats:

Firstly, it’s time-consuming. With touring and staging, most productions happen overnight or a day before, and there is never enough time to set everything up. With the sling solution, every single know has to be done manually every time the stage is set up. There is no reliable way of “pre-rigging” the slings, which means a lot of on-sit time and resources.

Secondly, the slings leave much room for human error. Rigging equipment from slings demands a high level of skill and expertise because “a production company’s reputation is hanging from it”, a famous phrase among riggers to denote the importance of doing their job right.

As an innovation-driven company, Design Quintessence has designed and developed a handful of successful solutions. In 2017, DQ held a workshop on rigging techniques in three states. Listening to riggers talking about the complications of hanging screens from truss structures, coming up with a solution became a job for our in-house R&D department. As it turned out, the answer was as simple as adding a centre chord to the truss.

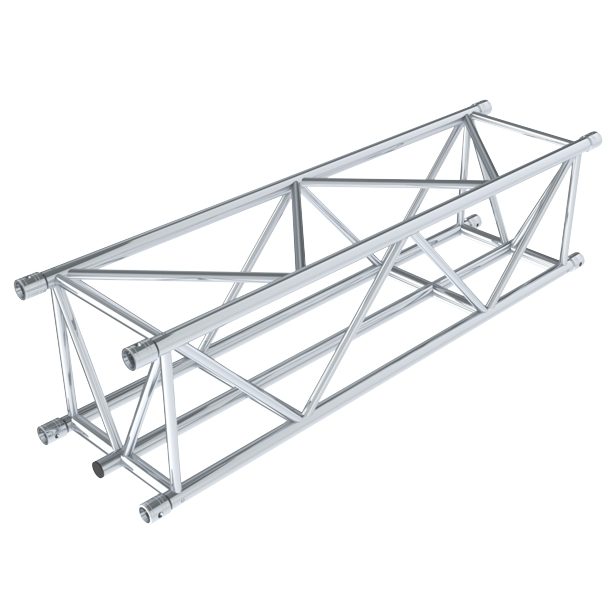

The F45 Truss is based on the F44P 400mm x 400mm truss design for applications such as LED screens where balanced centre rigging of equipment on the truss is essential. Because it is based on the F44P Truss design, F45 Truss can connect to all standard F44P junctions or sleeve blocks, so you use your existing F44P Truss to build the rest of the structure! A central chord with ladder-style horizontal bracing on the bottom face of the truss allows the equipment to be clamped directly onto the centre chord. This solution negates the need to balance the load by slinging or bracing across the two bottom chords to provide central rigging points as would typically be necessary on a square format truss. The ladder-style horizontal braces create increased clear hanging space along the chord compared to the hanging space on the outer chords. Clamping screen panels directly to the centre chord produce a cleaner and sleeker look.

Patrick Withers from The Music Box is clearly impressed, “On our first test build, we found around an 80% saving in labour attaching the first row of a 10m wide screen simply because we could clamp directly onto the centre chord. We can see the F45 Truss being used for general lighting and AV setups, making it so easy to balance your load.” Adding “… and there was no adjustment necessary. It’s a no-brainer!”

Becoming one of our best-selling products across Australia, the five-chord truss is already a successful design. A solution that is very simple and yet, it perfectly satisfies the need it was intended for.