Truss load charts can be confusing.

There are multiple rows and columns of numbers and a lot of acronyms to figure out. In this tech tip we are going to demystify some of that information. To begin with, let’s look at a load chart in overview.

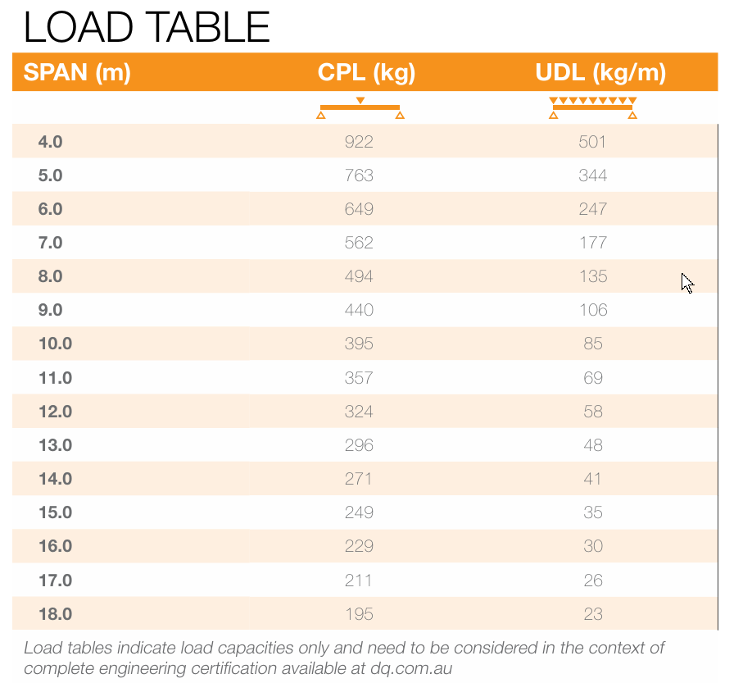

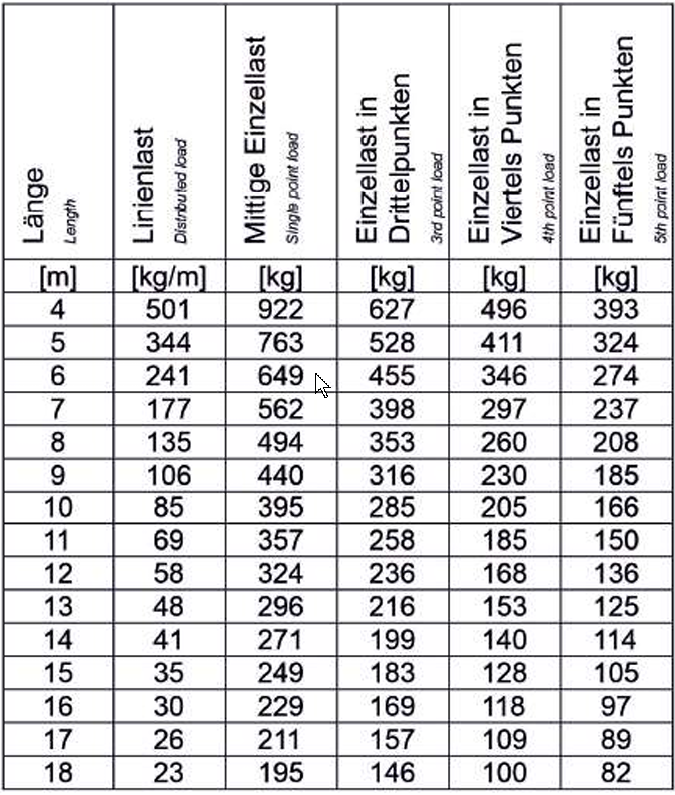

These two load charts show 2 common styles that you are likely to see for any truss. They contain load ratings for a range of span lengths and a range of load scenarios for each of those spans.

This information can be used to estimate the suitability of a particular truss span and size for the job prior to sending it to an engineer for final calculations. But before we start reading the chart we need to understand the limitations that apply to these charts.

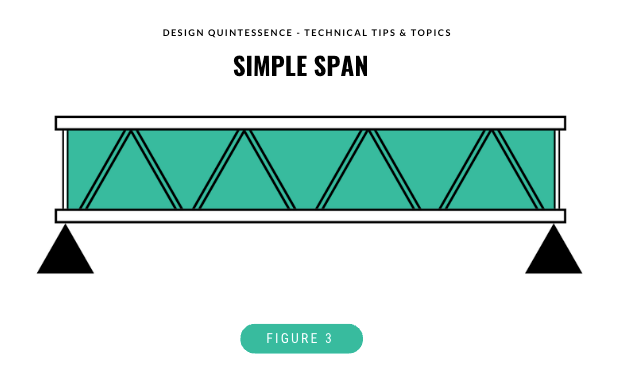

These load charts cannot cover every possible arrangement of truss, supports or structures. The load charts are calculated based on simple spans e.g. a truss of a given length supported at each end. If your truss suspension is anything other than that scenario, the load chart is not applicable, and your scenario should be calculated by an engineer.

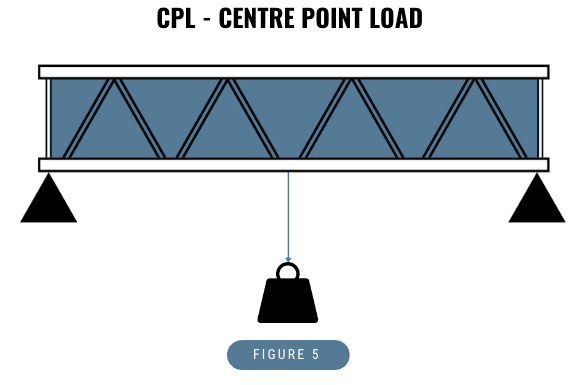

So what do these terms mean?

UDL, CPL, 3PL, 4PL and 5PL!

All those three letter acronyms we not only need to know, we also need to understand them to get an idea of what the truss can handle. Let’s look at them one at a time.

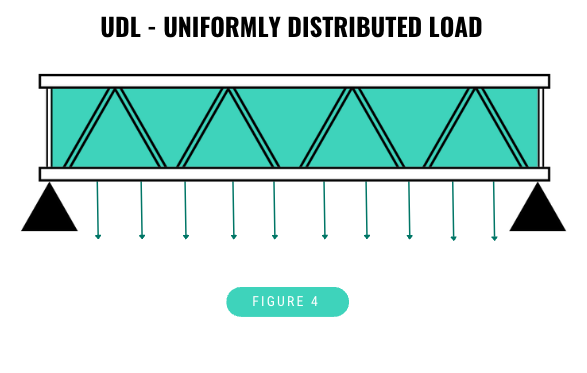

Uniformly Distributed Loads are one of the easiest and also quite common loads that we look at in our world. A UDL is exactly as it says, a load that weighs the same for any given distance across the entire truss. Examples of these types of loads are LED Screens, curtains or even an entire truss filled with evenly spaced, identical lights. The rule of thumb is that the load must be attached at no more than 1m spacing along the truss and that it must be a consistent weight across the entire truss.

Load charts for these types of loads will typically be expressed in kilograms per metre and so to work out the total load you multiply the rating by the length of the span.

E.g. F34 9m span has a rating of 106kg/m

The maximum distributed load you could apply would be 9 x 106 = 954kg UDL

The forces transfer through the truss along the main chord(s) and the braces to the hoists.

This scenario puts the bottom chord in tension, the braces in alternating tension/compression and the upper chord in compression.

The truss is in equilibrium and remains stable.

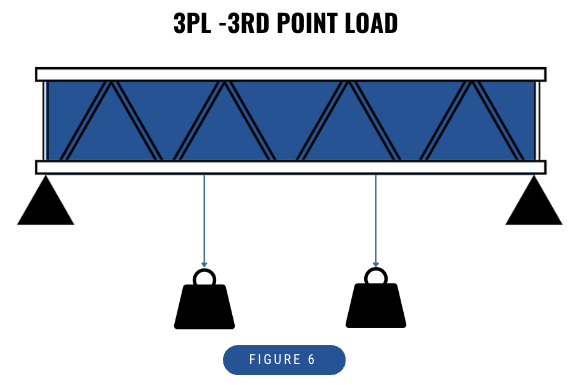

3PL, 4PL and 5PL – The last 3 of our acronyms are often the most misunderstood. They stand for 3rd point load (3PL), 4th point load (4PL) and 5th point load (5PL).

What this means is an equal load placed at the points that divide the truss span into thirds (3PL), fourths (4PL), and fifths (5PL).

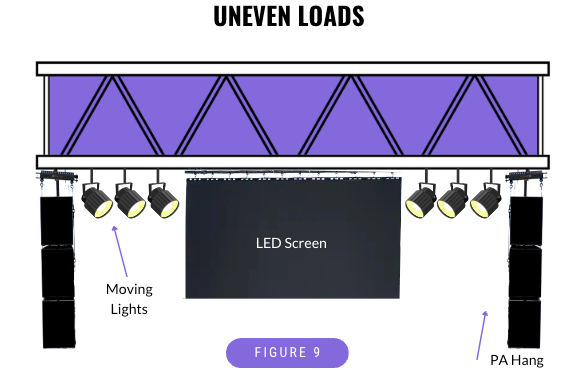

What isn’t covered?

As previously mentioned, load charts only cover simple spans and a limited number of load scenarios.

Of course, in the real world we often deal with complex loading scenarios, multi-point suspension and a range of external loads such as wind.

It’s impossible to provide a load chart for any scenario imaginable so it’s important to understand the limitations of the load charts, use them to estimate the correct truss required for the project and then have the system calculated by an engineer for final checking and approval.