A brief introduction

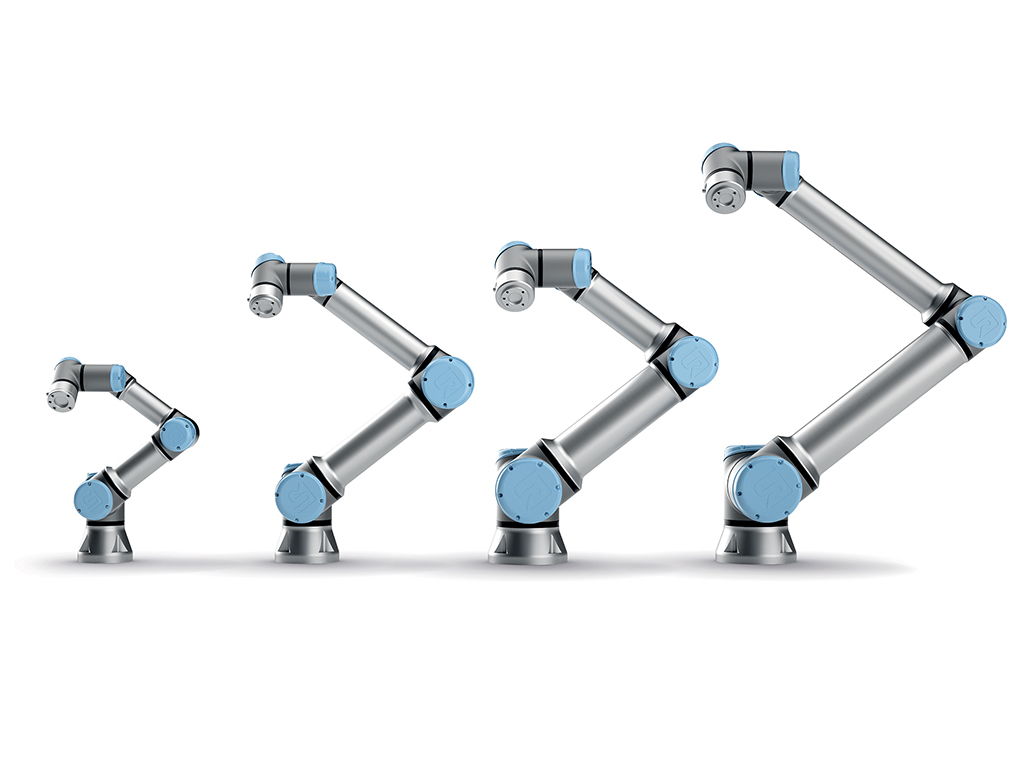

Around July 2022, we were approached by a client to design and manufacture a case for their new product, a UR10e Universal Robot extension. The Universal Robots is an industrial collaborative robot arm that can be programmed to work alongside humans and could be equipped with different peripherals for varying applications.

Like many other sensitive equipment, these robots come in Styrofoam packaging, which, while light, is not durable and can hardly be recycled. The client decided to replace the Styrofoam packaging with a more sustainable and durable solution that can protect the robot throughout its life cycle from sales to use.

We were met with challenging criteria from our clients as they had two requirements that were crucial to transporting their robot components to an expo in the US; the overall weight of the case must be less than 12kgs and it had to be ready for dispatch in two weeks.

The Solution

For some time, we have been assessing the use of composite panels to manufacture lighter-weight cases for the market. Our team was able to source the material to meet these growing demands, a revolutionary 100% recyclable flight case panel which is a game-changer in the case manufacturing world.

With our newly sourced material, we thought this would be an ideal scenario to test out these panels. We took this opportunity to use and apply these panels to create a case that would be both light-weight and durable, allowing clients to travel and fly within their weight limitations.

Our standard Ovation Cases are manufactured with high-quality birch plywood which make them heavier. These panels, in contrast, feature two main contradicting benefits: lighter-weight and durability.

Other key features of this material are:

- Reduction of the weight by 30%-40% as the panels are 80% lighter than the typical plywood. It does not, however, compromise on its strength as it still has the same strength as a regular birch plywood.

- High resistance to impacts caused by chemicals, humidity, weather, and liquids. As it is produced with polypropylene fibres and with its honeycomb design, it can withstand possible damages it can incur on a comparatively slower basis compared to any other materials.

- 100% recyclable as no glass fibres were used and fewer resources were required to produce the panels, making it eco-friendly and sustainable. In addition, it ensures long lifespan which reduces the need for replacements.

Our Design and Manufacturing department had to collectively brainstorm on whether our Adam Hall Birch Plywood was the best option for this project and source an alternative solution to the client’s requirements. Although the dense and robust plywood is of high-quality and industry-best for manufacturing Ovation Cases, it was not the ideal solution for this project.

We had to ensure that we deliver light-weight cases that are strong enough to protect the sensitive industrial equipment while being constrained by the time and weight limitations. However, having local facilities meant that we can design and build the Ovation Cases which also makes it possible to meet the client requirements and achieve a quick turnaround.

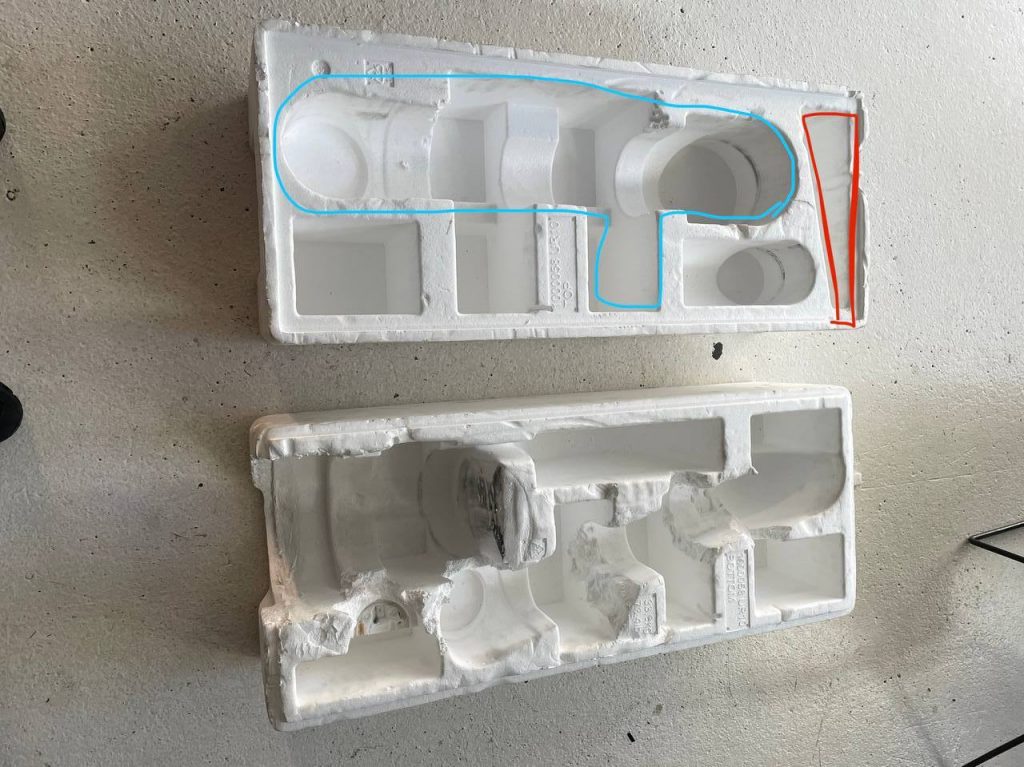

While minimal, the cases’ design ticked all the requirements that our client asked for, including the need for them to be wheeled around like a carry-on case. Another issue was the weight of our high-density EVA foam, to ensure the fit of the design, our team built a prototype to test the foam insert and trim the excess even further to keep only the essential blocks without compromising the protectivity of it.