Box truss is a versatile tool in the entertainment industry. It is light, configurable in many ways, and able to carry heavy loads. That said, it does have its drawbacks as well. When the load that needs to be supported from the truss must be centred it can be difficult to achieve. One method that is often proposed is hanging the box truss in a “Diamond” hang so that the load can attach to the lowest chord at the centre, in line with the rigging supports above. The question is, is that safe to do?

To answer that it is useful to understand how the loads applied to a truss are supported and spread through the chords and bracing.

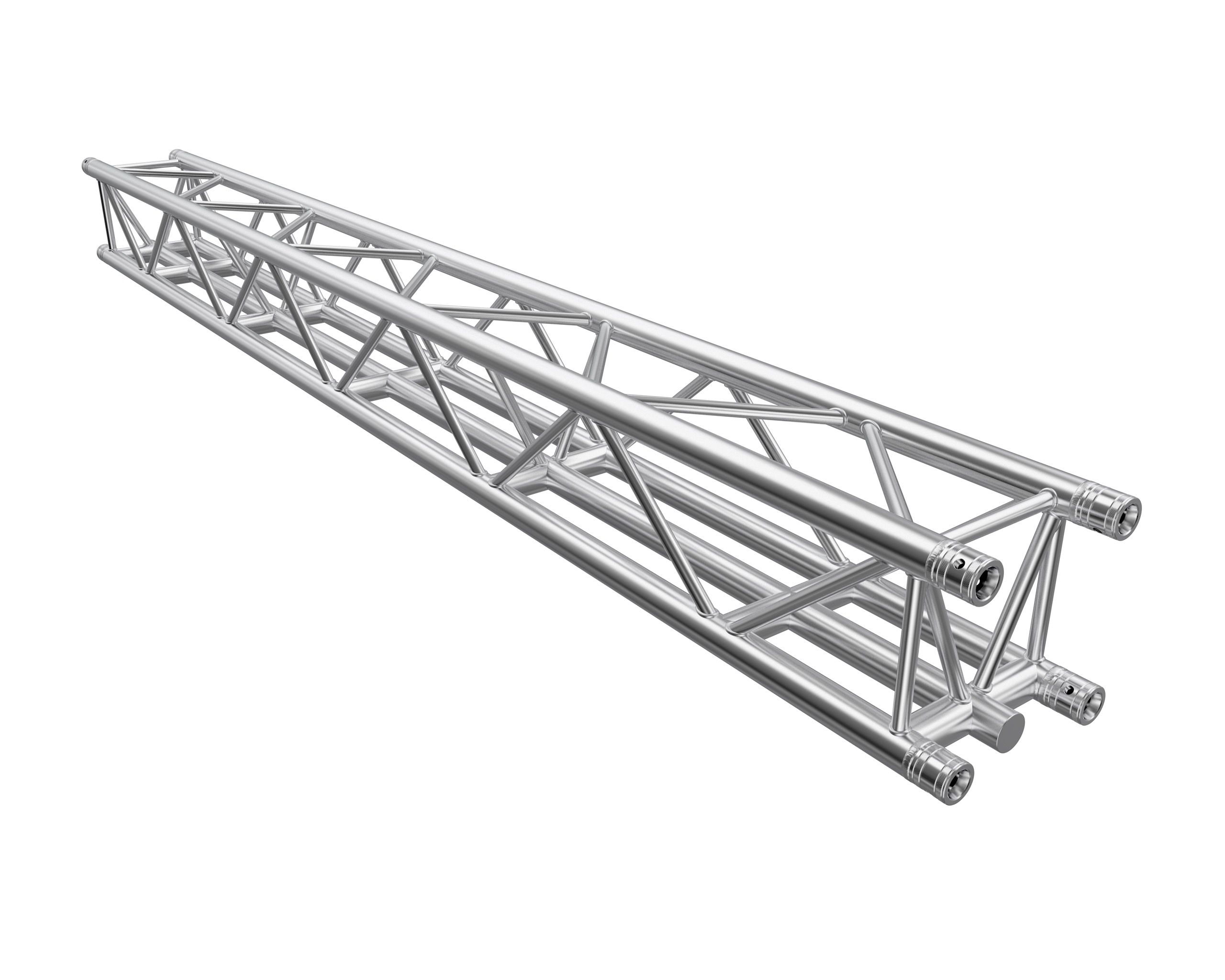

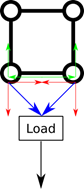

If we consider a typical box truss with a load hung on slings to bring it under the centre it looks like this (Figure 1):

Figure 1

The blue lines represent the force that the load is exerting on the truss. The vertical load acting through the sling applies two angled forces that apply through the sling to the lower chords and the bracing.

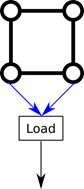

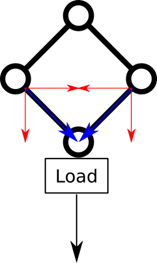

These two angled forces can also be represented as vertical and horizontal forces (shown here in red) that apply loads to the vertical bracing and the horizontal bracing. (Figure 2)

Figure 2

Those forces are counteracted by the bracing with an equal and opposite force (in green). (Figure 3) These opposing forces balance out the horizontal and vertical loads leaving the total force in equilibrium. With those forces in equilibrium, the truss does not roll or twist and is going to be stable.

Figure 3

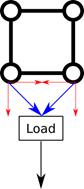

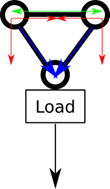

So what happens when the truss is hung as a diamond? E.g. rotated by 45 degrees

Figure 4

As shown in the diagram above (Figure 4), the load applies a vertical load to the lowest chord of the truss which results in two angled forces applied through the bracing on the lower faces. Those braces are now acting much like the sling in the example above and produce the same vertical and horizontal forces as before.

It should be obvious that there is now no structural element that is directly opposing the vertical and horizontal forces being applied to the truss. The risks here are that the truss can be deformed, squeezing the outside chords together, and if the load is high enough this can cause catastrophic failure of the truss. Because this is an orientation of truss that is not considered by the engineering reports it also means that all load charts do not apply to the truss when loaded in this way.

So how can the need to hang our loads in the centre be managed. There are many circumstances where this is desirable. Hanging LED screens is one of the most common ones but hanging lights centrally makes balancing the truss easier and is easier to work with also. The first option is to use tri-truss with the apex down.

The vertical loads are dispersed up into the suspension hardware for the truss and the horizontal bracing resists the squeezing of the horizontal forces.

The drawback to this option is that tri truss is not as strong as box truss which limits the loads that you can hang from it.

The most recent change in the truss world has been the introduction of 5-chord truss which solves these problems in one design.

Figure 5

By combining the strength of box truss with the lower central chord supported by diagonal bracing and much heavier horizontal braces, the 5-chord truss allows for simple and efficient hanging of central loads on the truss while avoiding the potential damage from “Diamond” hangs.

Remember, truss is shiny and might sparkle, but it is not a diamond and should not look like one. Using the right truss for the job is the best way to do it.